¶ 1. Clean the lattice glass plate

A clean lattice glass plate can increase the adhesion to the model, reduce the model falling off during the printing process, and improve the printing success rate.

¶ When to do it?

Before each printing, you need to check whether there is dust or residual consumables on the lattice glass plate. If there is any, it needs to be cleaned before printing.

¶ How to do it?

Use a non-woven cloth dipped in water or alcohol to clean the glass plate.

¶ 2. Lubricate the optical shaft

The three optical axes and sliders require regular lubrication. Proper lubrication ensures smooth slide movement, reduces noise and extends service life.

¶ When to do it?

Check and grease every 15 days.

¶ How to do it?

Apply grease to the optical shaft, slide the slider up and down, and repeat several times to distribute the grease evenly on the optical shaft.

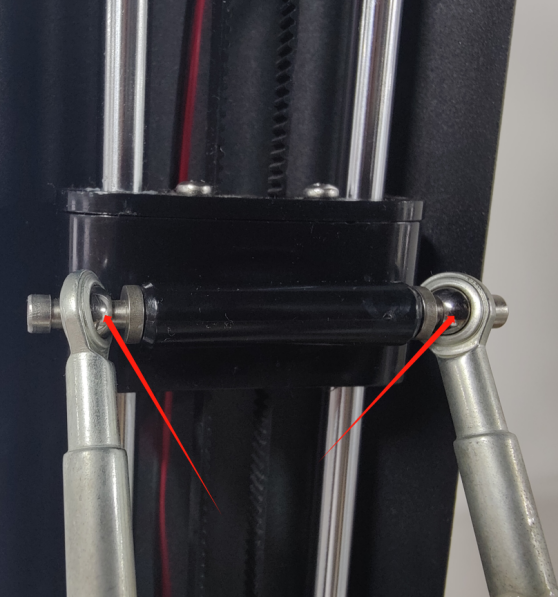

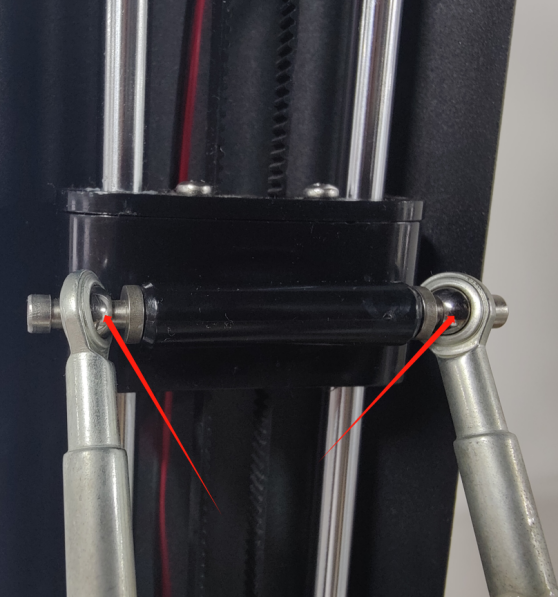

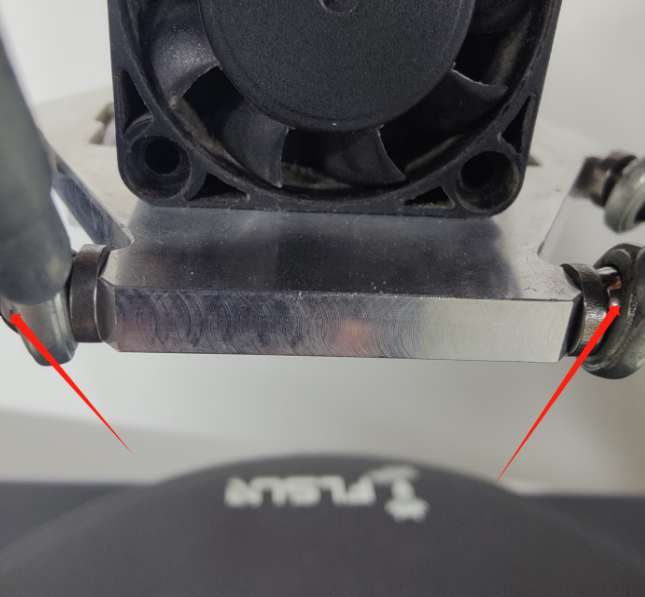

¶ 3. Lubricate the parallel arm

The parallel arm serves as a motion joint to provide movement of the effector module and requires regular lubrication. Proper lubrication can ensure smooth movement and extend service life.

¶ When to do it?

It should be inspected and greased once a month.

¶ How to do it?

Apply grease to the fisheye heads at both ends of the parallel arms.

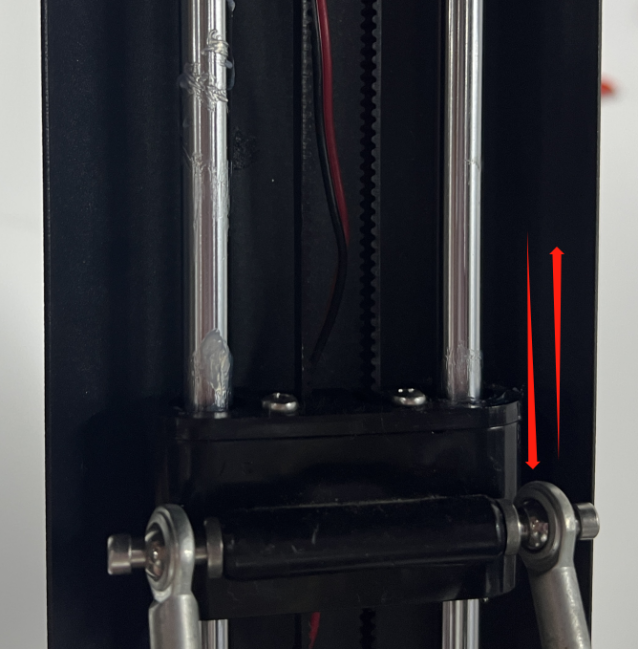

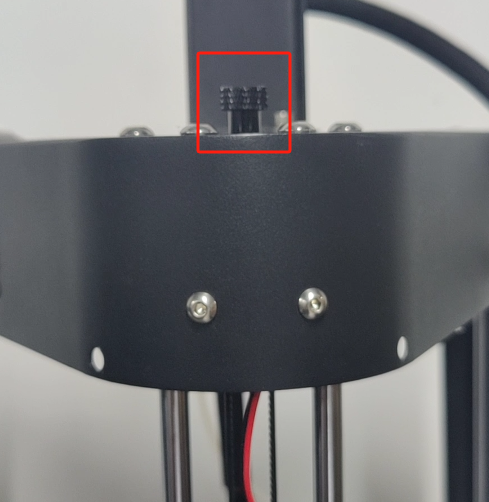

¶ 4. Check the belt

The driven slide provides precise movement to the machine.

¶ When to do it?

The belt should be inspected every 2 months and readjusted as appropriate.

¶ How to do it?

Tighten the black nut in the picture according to the tightness of the belt. Clockwise tightens the belt, and counterclockwise loosens the belt.

Video of adjusting belt tightness:

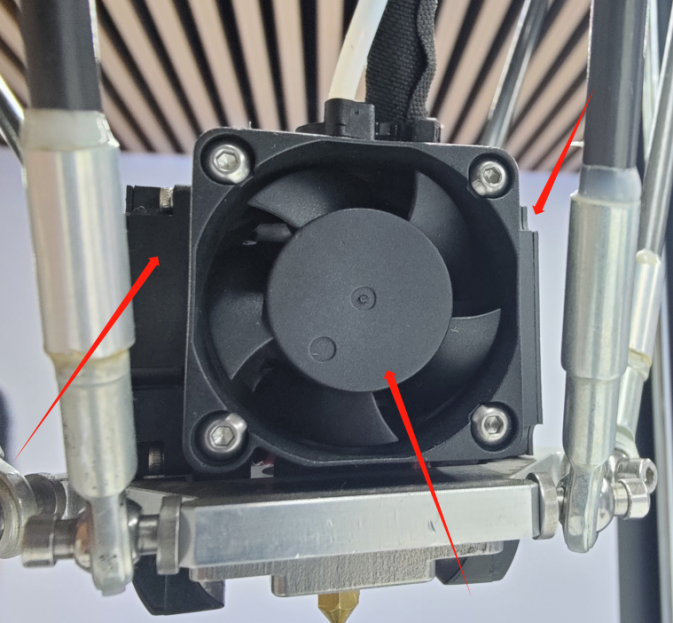

¶ 5. Clean the cooling fan

The three fans on the effector should be inspected regularly for accumulation of dust and debris. to ensure smooth operation and long life.

¶ When to do it?

It is recommended to inspect the fan every 15 days to clean any debris or dust that may have accumulated around the blades

¶ How to do it?

With the printer turned off, use compressed air or a fine soft brush to remove dust or debris from the fan blades

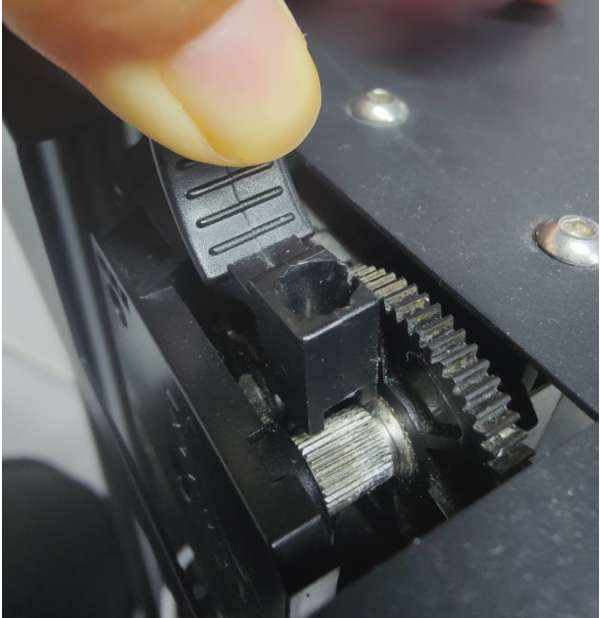

¶ 6. Clean the extruder

Cleaning debris from the wire feed roll reduces the risk of stockouts and jams to ensure smooth operation and long life

¶ When to do it?

It is recommended to check every 15 days and clean the consumable debris on the wire feed wheel.

¶ How to do it?

Clean the inside of the extruder. Completely loosen the adjustment knob on the extruder to open the extruder, and use the supplied brush to clean the remaining debris and debris inside the extruder.

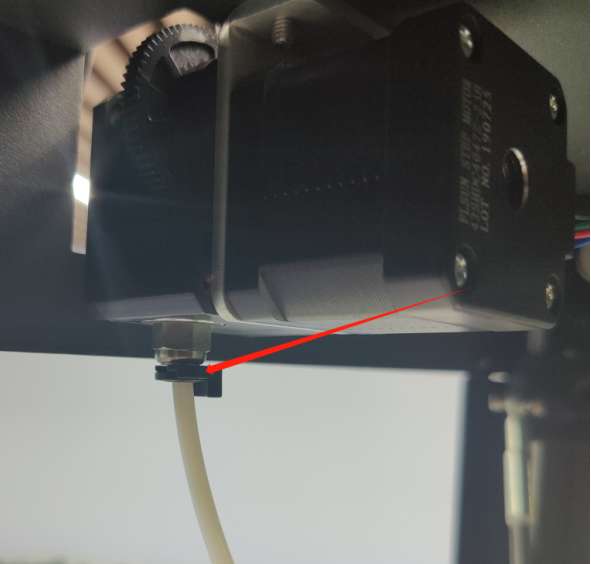

¶ 7. Check the pneumatic joint

Regularly check whether the fixing buckles on the pneumatic joints on the side of the extruder and the effector module are detached or damaged. If the buckles are detached or damaged, the material tube will not be firmly fixed, resulting in material blockage.

¶ 8. Shaft motor bearings

Proper lubrication ensures smooth operation and long life.

¶ When to do it?

It is recommended to check once a month and apply lubricant

¶ How to do it?

Remove the aluminum profile cover, turn the motor and drip liquid lubricant onto the bearings