¶ 1. Nozzle clogging:

Heat the nozzle to 240°, use the silver needle in the gift bag to clear the nozzle several times, click feed, and observe whether the filament is extruded normally. If it can be extruded normally, it is judged that the nozzle is clogged. If it still cannot be extruded normally, you need to continue to check down.

¶ 2. The material pipe is blocked:

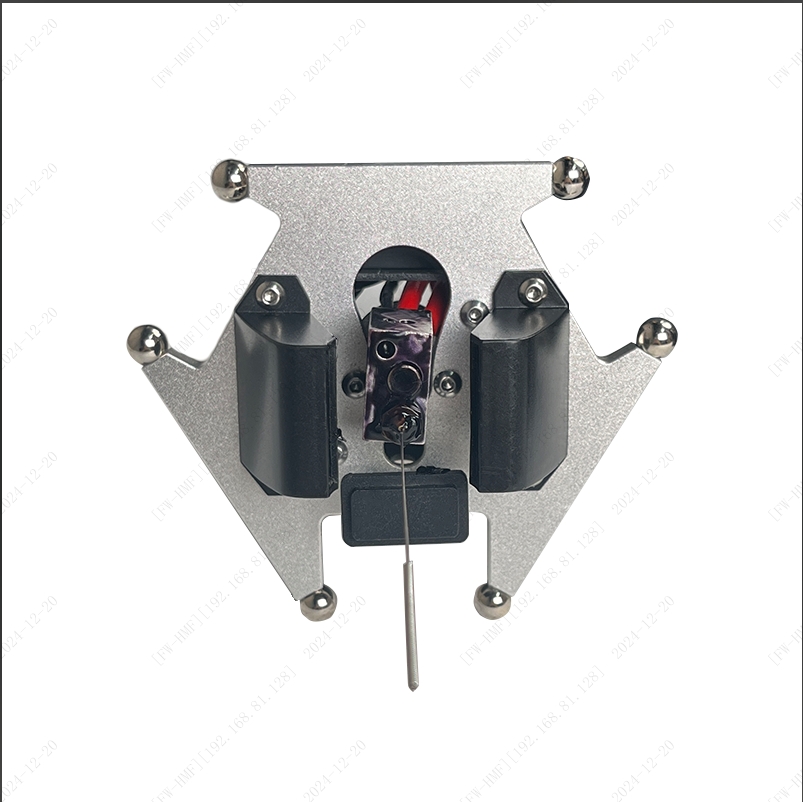

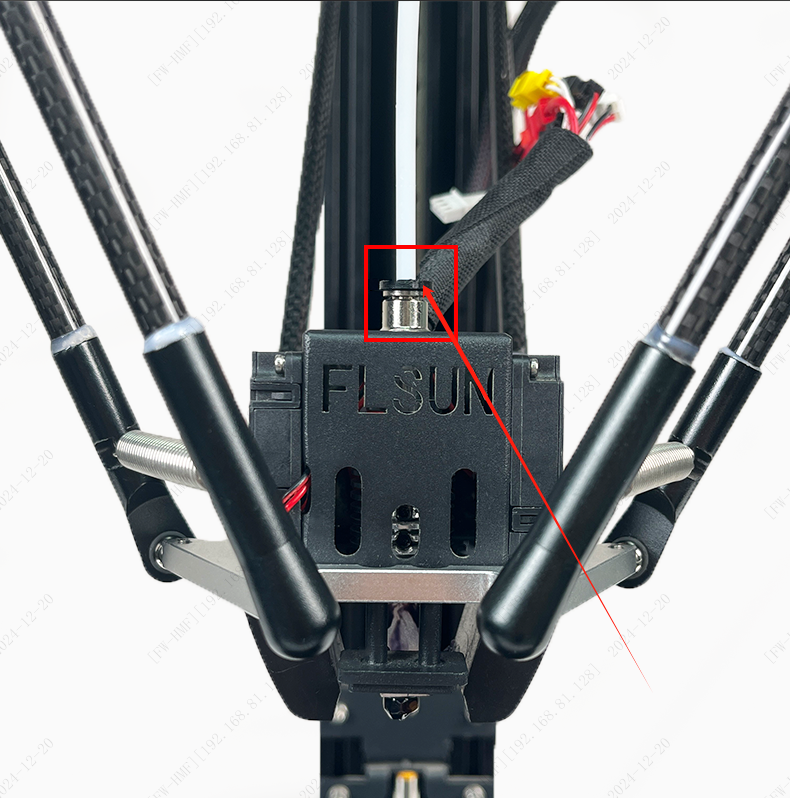

Take off the black buckle on the tube of the effector, press the pneumatic connector, and pull out the tube.

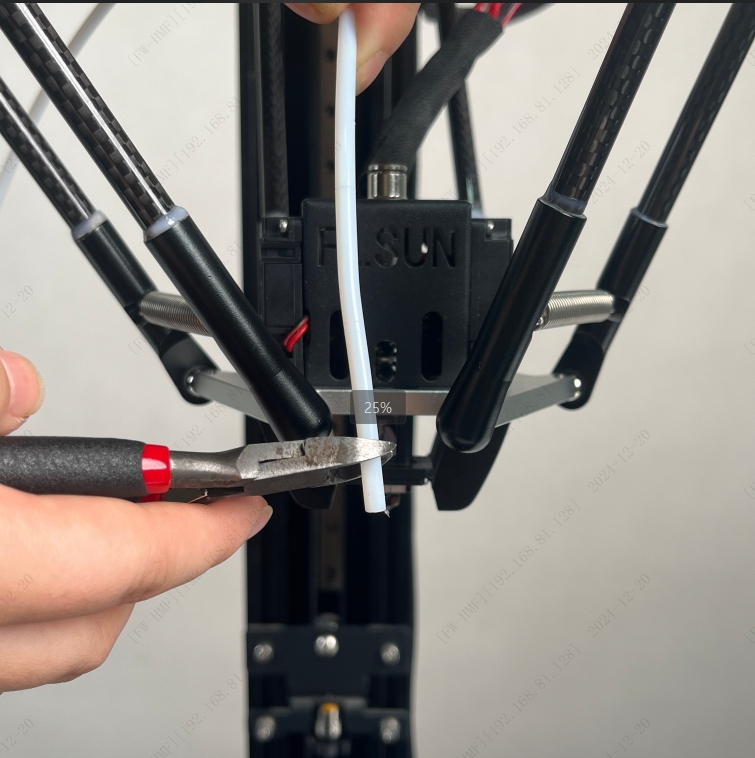

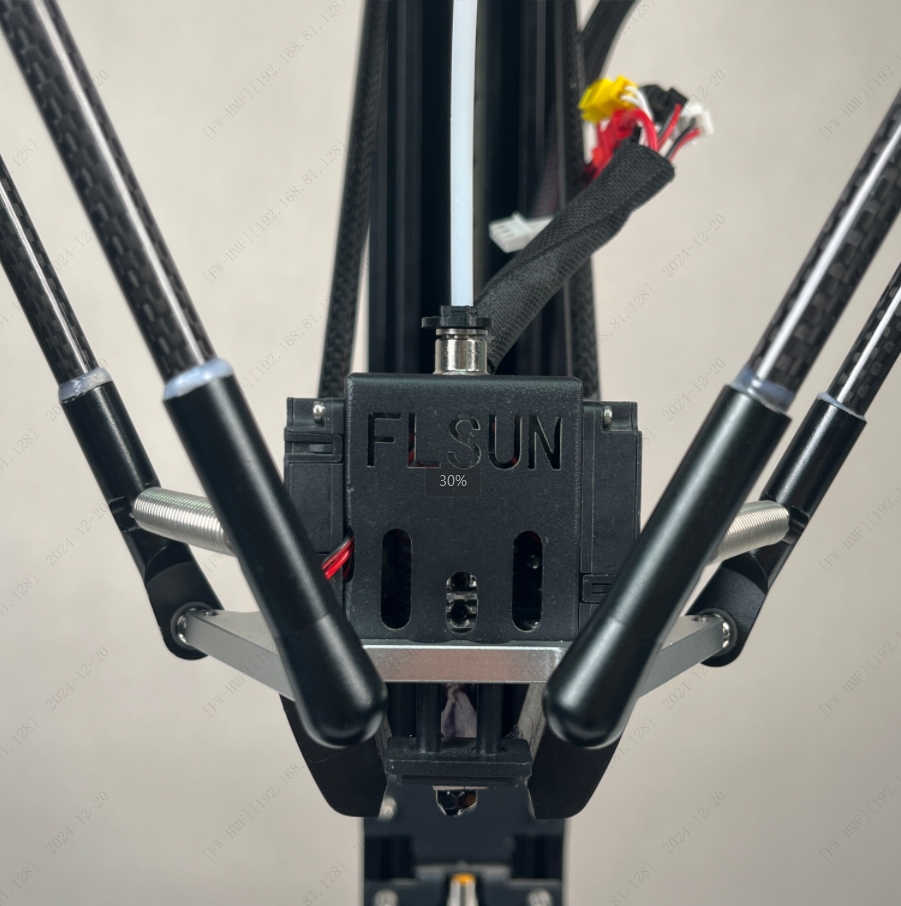

Check whether there are residual filament in the material tube. If there are residual filament, you can manually clean up the remaining filament. If manual cleaning is not possible, you need to use diagonal pliers to cut off the material tube with residual filament, and then put the material tube back, make sure that the material tube is inserted to the end and then install the black buckle.

Then perform the extrusion test again to see if the material is still blocked. If it can be extruded normally, it is judged that the material pipe is blocked. If it still cannot be extruded, continue to check down.

¶ 3. Throat blockage:

Disassemble the V6 module in the effector module and check whether there are residual filament in the throat. If there are residual filament, you can use tools to clean them. If it cannot be cleaned, the throat pipe or the entire V6 module needs to be replaced individually.

Video link for dismantling the V6 module: https://www.youtube.com/watch?v=ibZX1Mv1UoE

¶ 4. Extruder blockage:

First unscrew the thumb screw of the extruder, use a brush to clean the filament debris on the surface of the extruder gear or disassemble the extruder for comprehensive cleaning.

Video link for dismantling the extruder: https://www.youtube.com/watch?v=pEK0rUkRNBA