¶ 1. Abnormal noise from the fan

Check whether the fan is deformed and try to adjust it manually. If it doesn’t work, please contact the after-sales email address to replace the fan: service@flsund3d.com (if the machine is within the warranty period).

¶ 2. Abnormal sound of extruder

(1) If the extruder makes a slight clicking sound when clicking on the feed, it is caused by the feed speed being too fast, which is a normal phenomenon.

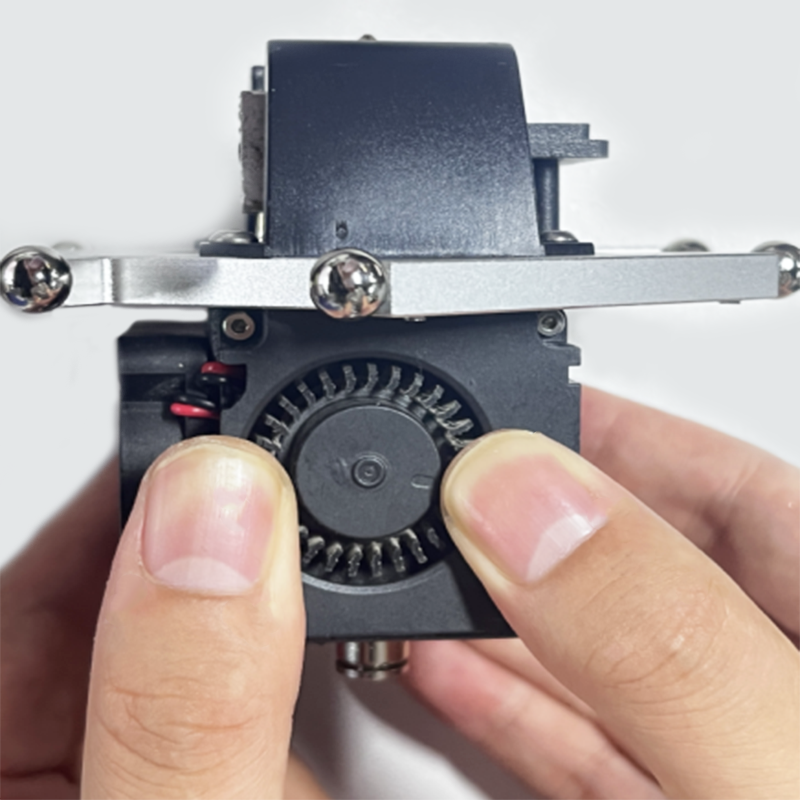

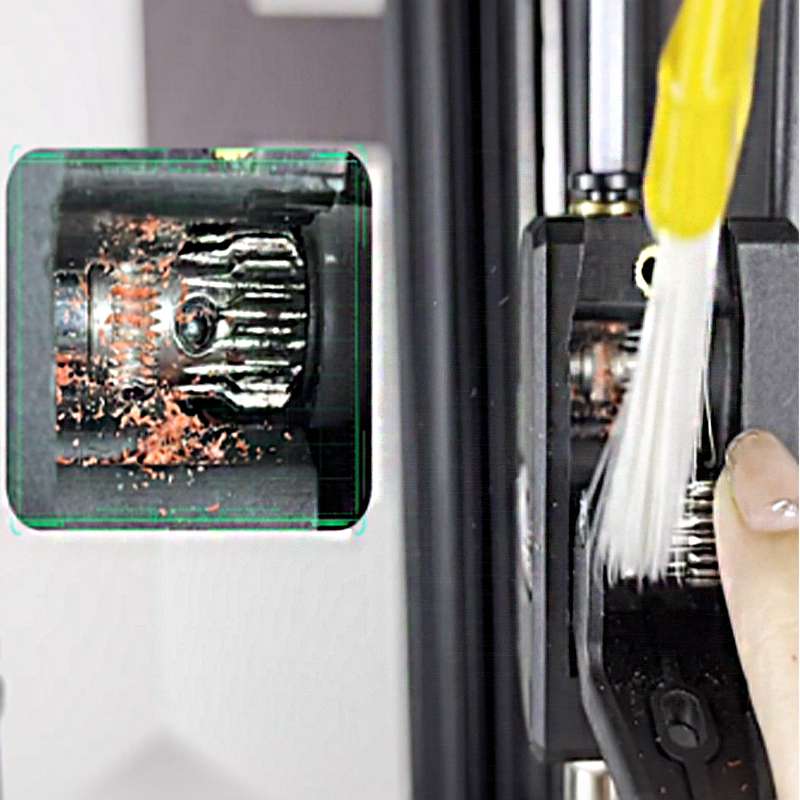

(2) Check whether there are residual consumables in the extruder. If there are residual consumables, please disassemble the extruder for cleaning.

Video link for dismantling the extruder:

https://www.youtube.com/watch?v=pEK0rUkRNBA&t=58s

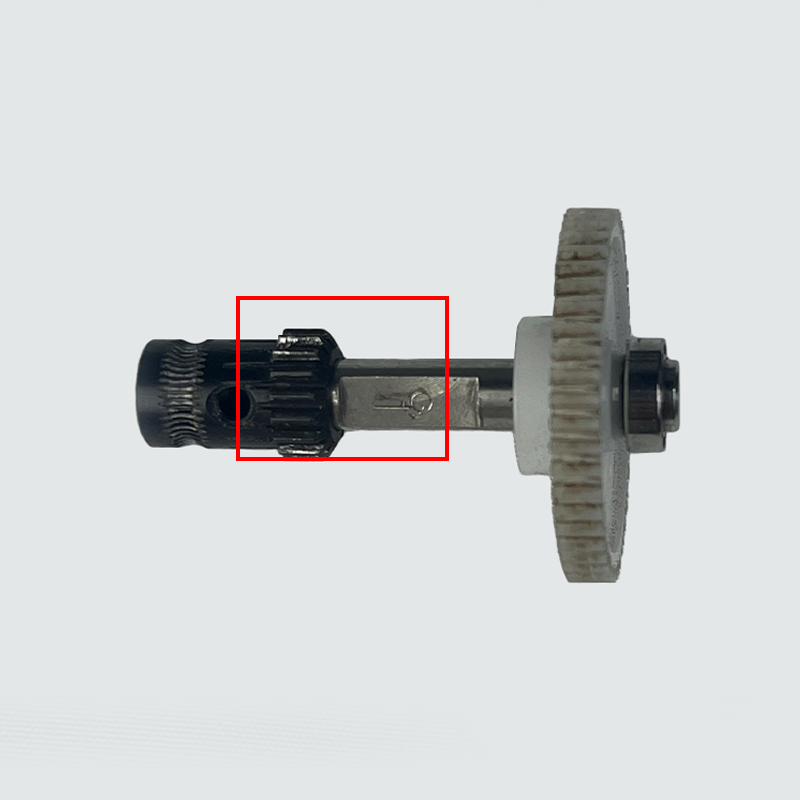

(3) Check whether the wire feed roll coaxial with the plastic wheel is loose (that is, the rotation of the plastic wheel and the wire feed roll is out of sync). Tighten the jackscrew with a hex wrench.

If there is an obvious stuck feeling when turning the wire feed wheel at the handle, please contact the after-sales mailbox to replace the gear kit.

¶ 3. Abnormal sound of line rail

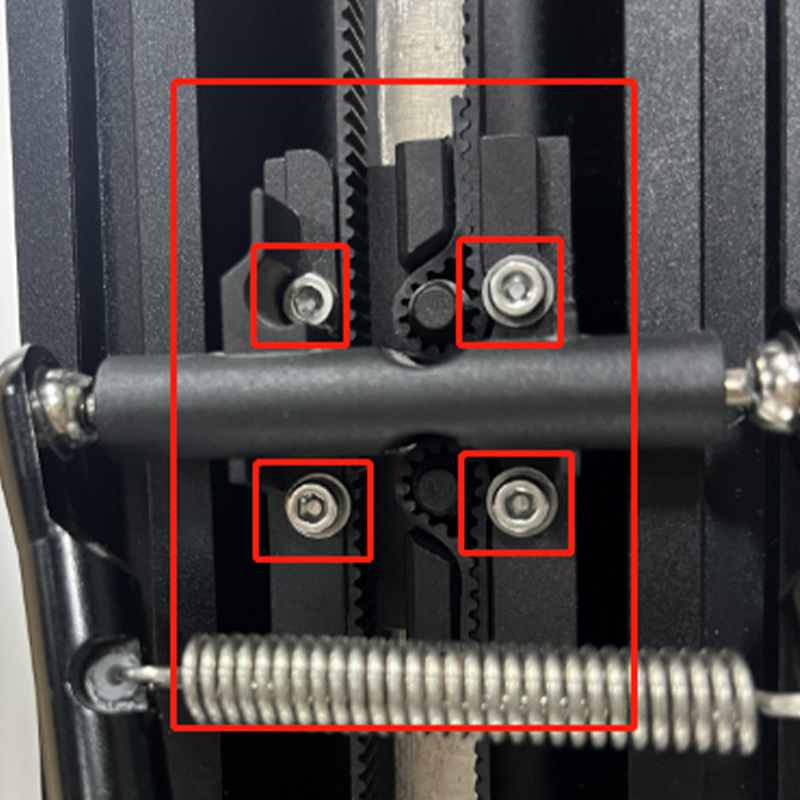

(1) Manually slide the slider to confirm whether there is obvious resistance or ball noise. If there is resistance to sliding, please apply grease to the track on the side of the line rail, and slide the slider up and down to make it fully lubricated. If there is no effect, please contact the after-sales mailbox to replace the line rail.

(2) After tightening the screws of the pulley, shake the pulley left and right. If the pulley is loose, it means that the noise is caused by the wear of the line rail. Please feed the information to the after-sales mailbox for processing.