¶ I. Hot end kit

The heating rod is used to heat and melt the filament, with a power of 80W

The temperature sensor is used to detect the temperature of the heating block, model NTC 100K 3950B.

¶ II. When to replace

¶ 1.Replace the heating rod

The extruder does not heat or the heating speed is too slow

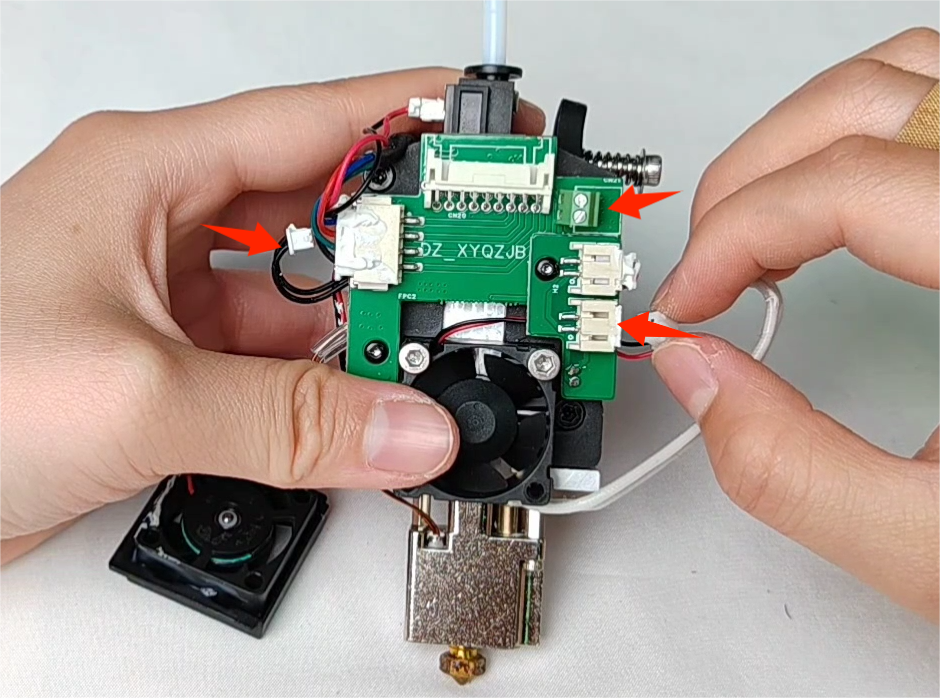

Heater extruder not heating at expected rate

The Flsun after-sales service team determined the fault caused by the heating rod through analysis

¶ 2.Replace the temperature sensor

Shut down:Extrude below minimum temp

The temperature display is abnormal, and the temperature displayed without heating is not room temperature.

The after-sales service team determined the fault caused by the temperature sensor through analysis

¶ III. Tools used

H1.5 Allen wrench

H2.0 Allen wrench

H2.5 Allen wrench

New heating rod and temperature sensor

¶ IV. Replacement steps

Note: If there is filament in the effector, please heat and exit the filament before replacement, and then disassemble it; the disassembly operation needs to be performed when the machine is powered off.

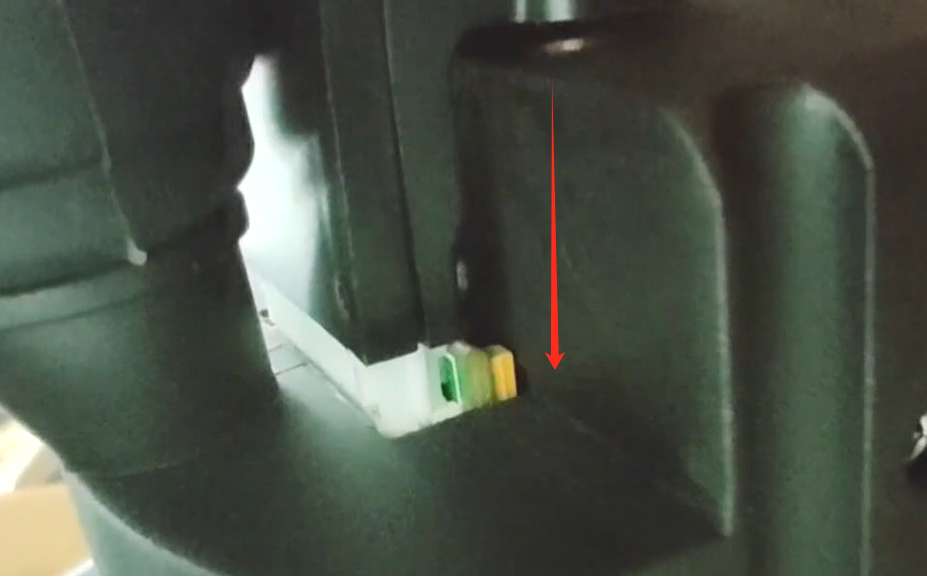

¶ 1. Use the H2.0 Allen wrench in the accessory box to remove the two screws that fix the effector line card and remove the effector line.

¶ 2. Use the H2.5 wrench to remove the two screws that fix the effector fan cover.

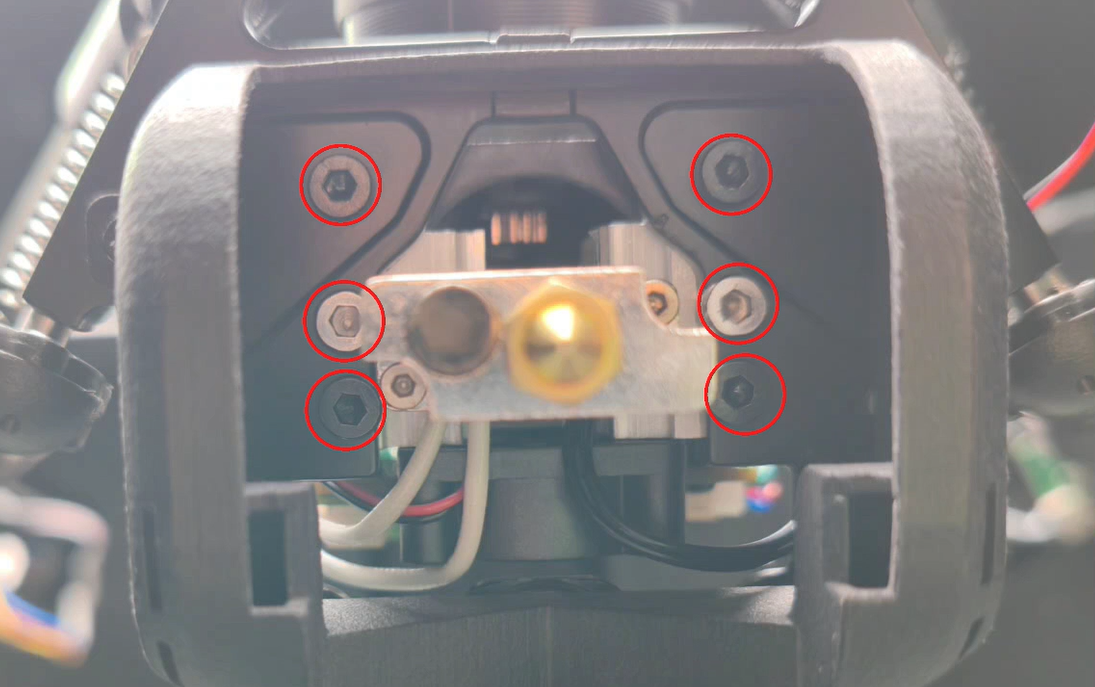

¶ 3. Use the H2.0 Allen wrench in the accessory box to remove the six screws that fix the hot end and extruder.

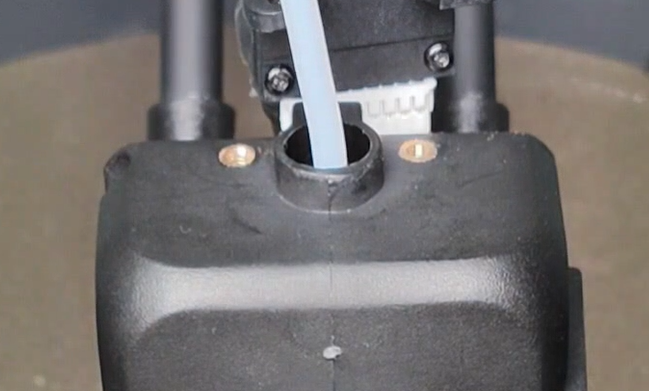

¶ 4. Carefully remove the silicone sleeve of the plastic rib tube, remove the nozzle, and take out the effector.

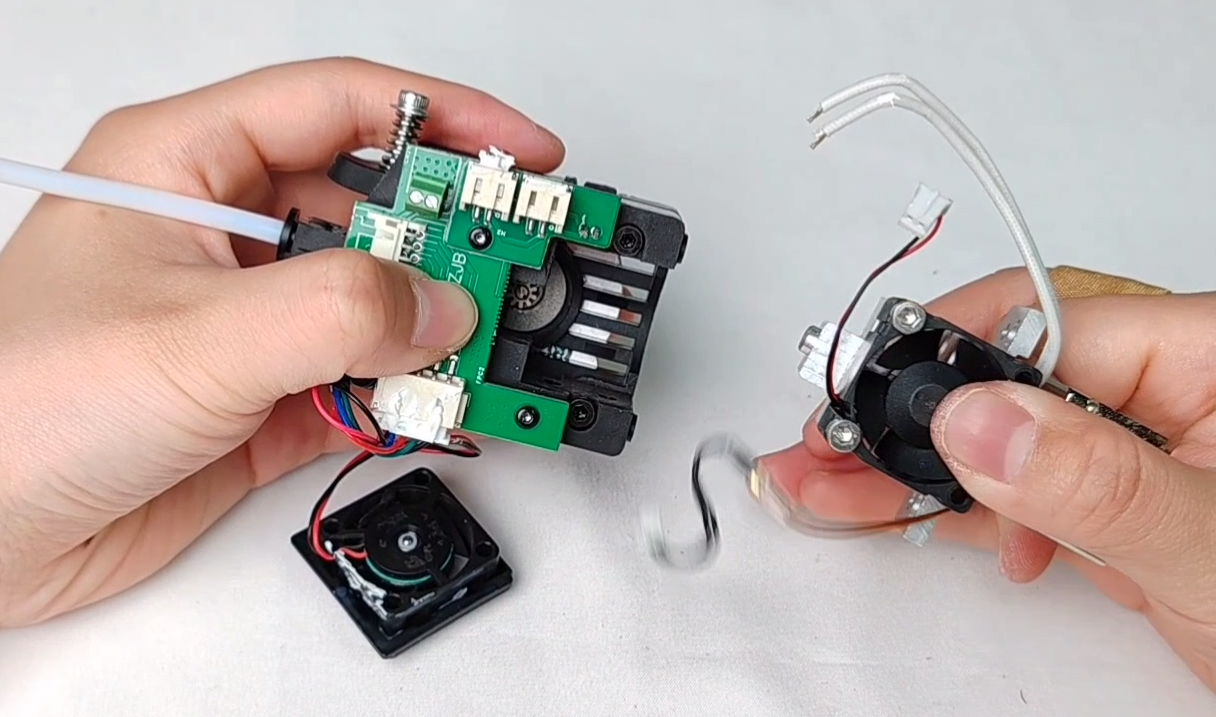

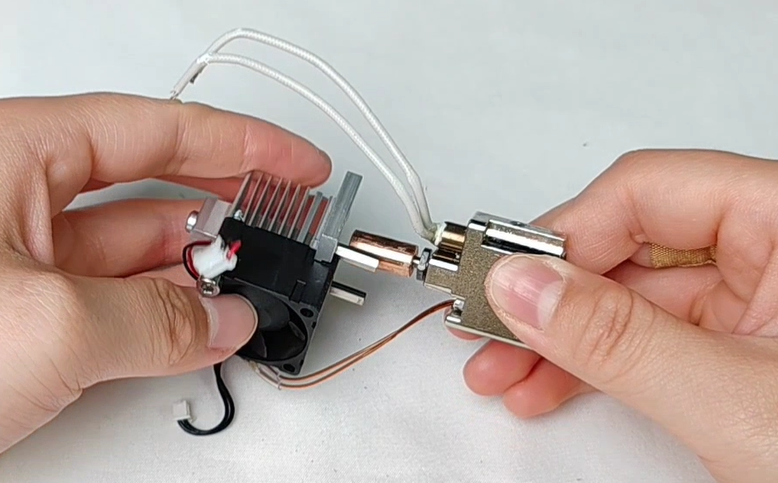

¶ 5. Take out the kit and remove the cooling fan fixed to the effector housing.

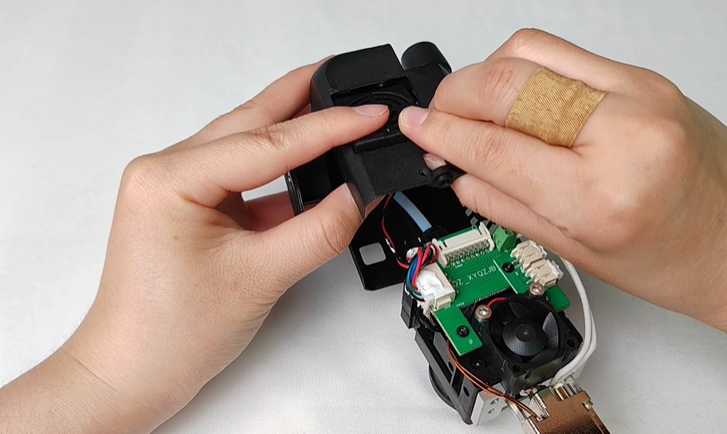

¶ 6. Use a flat screwdriver to remove the heater rod line; unplug the temperature sensor and fan terminal, and take out the entire hot end kit and fan.

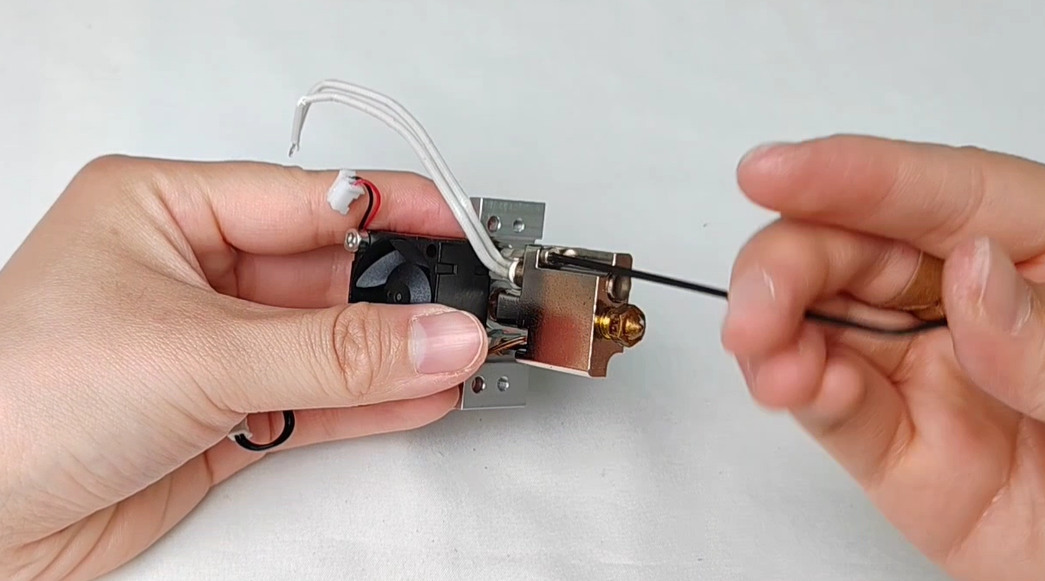

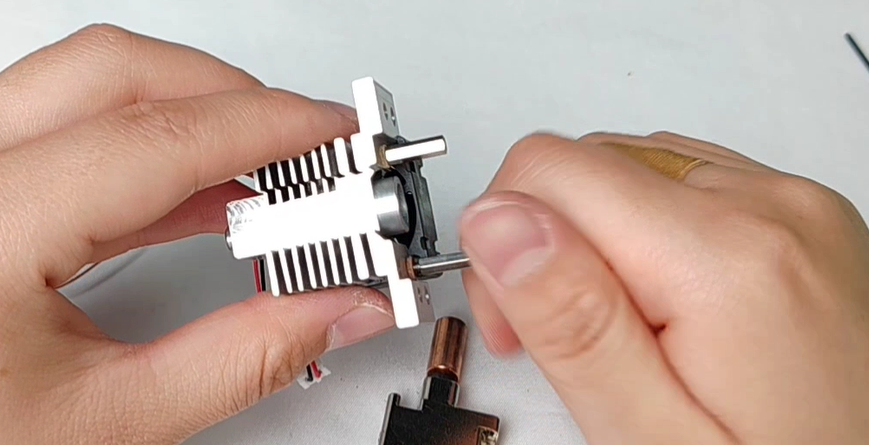

¶ 7. Use the H1.5 Allen wrench to remove the screws that fix the hot end kit and take out the hot end kit.

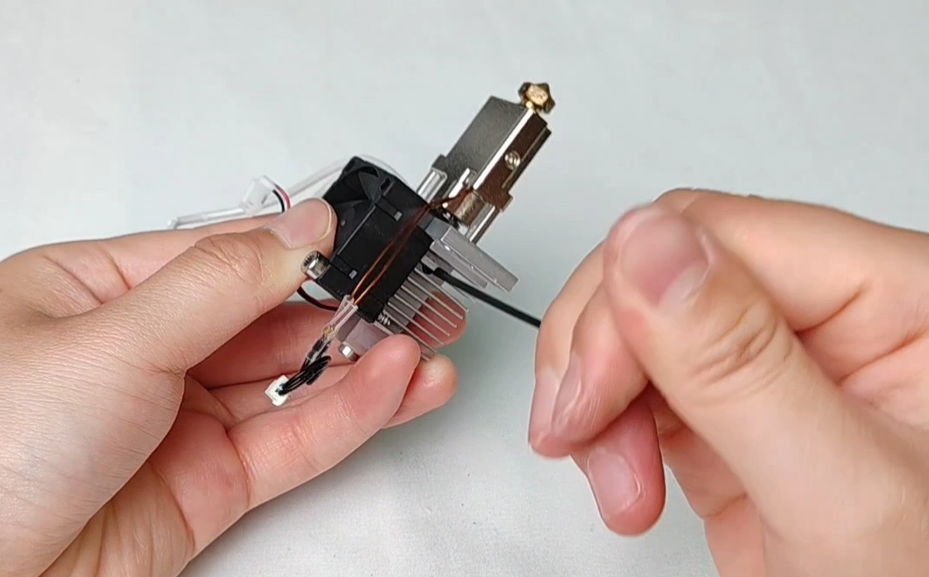

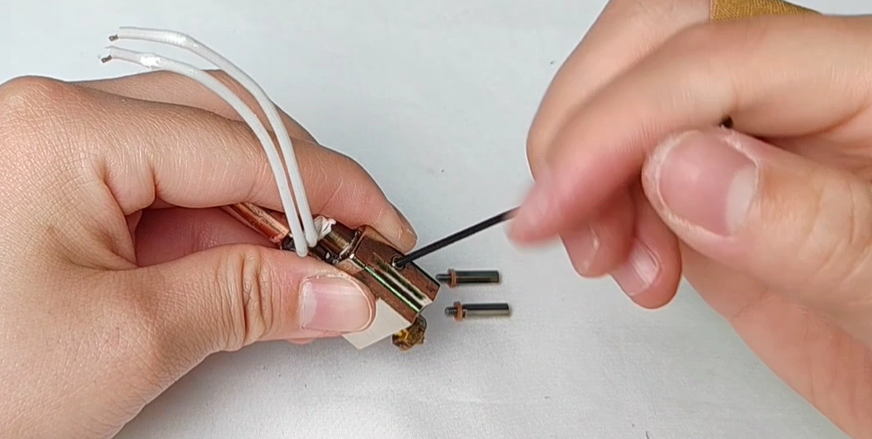

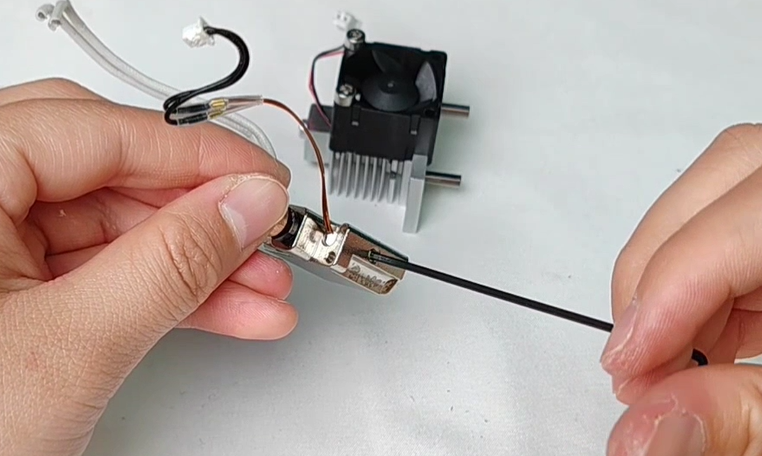

¶ 8. Loosen the screws that fix the temperature sensor and heater rod, and take out the temperature sensor and heater rod.

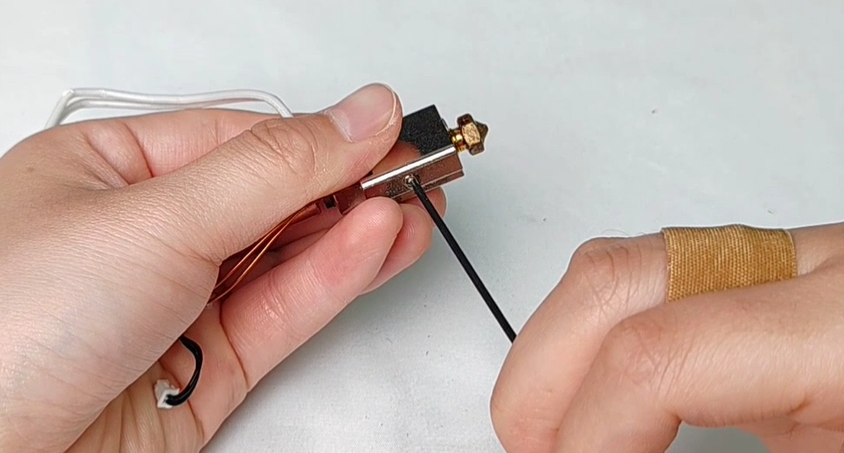

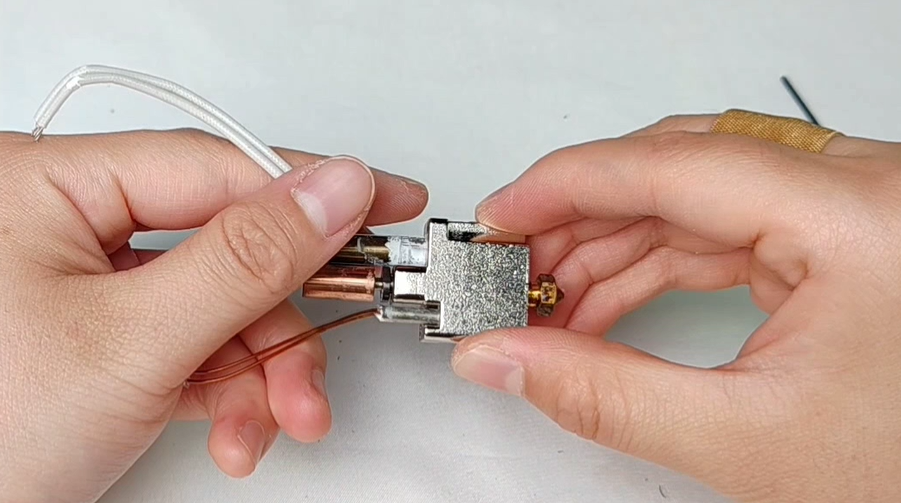

¶ 9. Install the new temperature sensor and heater rod.

Note:

¶ (1) When installing the hexagonal stud, do not forget the yellow gasket.

¶ (2) Do not tighten the screws that fix the temperature sensor too much to avoid flattening the iron head and damaging the temperature sensor.

¶ (3) When installing the effector cable, make sure that the effector cable is inserted to the bottom.