¶ 1. Filament detection module

When the printer detects that the filament cann't be inspected, the machine will pause printing.

¶ 2. When to replace

The filament detection module is damaged

¶ 3. Tools used

H1.5 Allen wrench

H2.0 Allen wrench

H2.5 Allen wrench

New effector adapter plate

¶ 4. Replacement steps

Note: Before replacement, please heat and eject the filament before disassembly; the disassembly operation needs to be performed when the machine is powered off, and pay attention to high temperature.

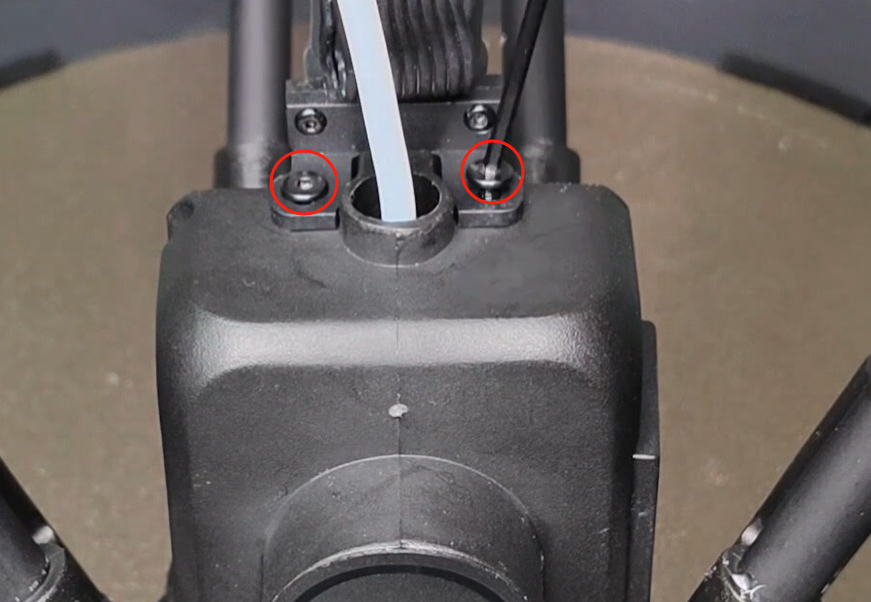

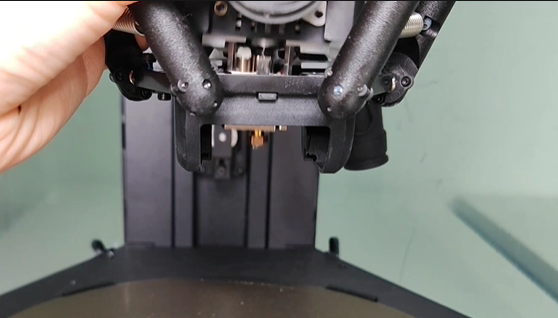

¶ (1). Use the H2.0 Allen wrench in the accessory box to remove the two screws that fix the effector line card and remove the effector line.

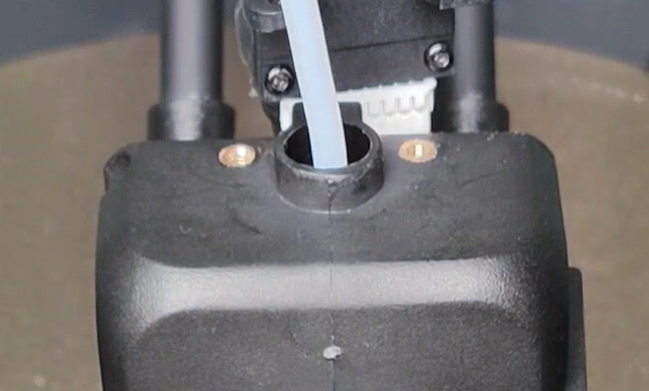

¶ (2). Use the H2.5 wrench to remove the two screws that fix the effector fan cover.

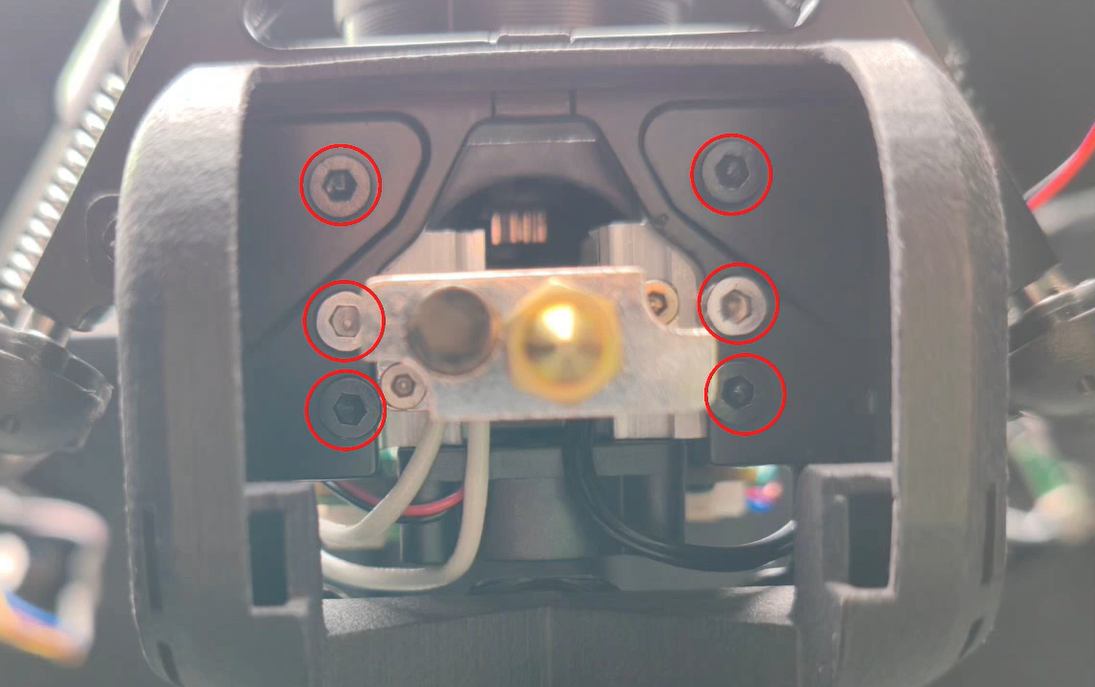

¶ (3). Use the H2.0 Allen wrench in the accessory box to remove the 6 screws that fix the hot end and extruder.

¶ (4). Carefully remove the silicone sleeve of the plastic rib tube, remove the nozzle, and take out the effector.

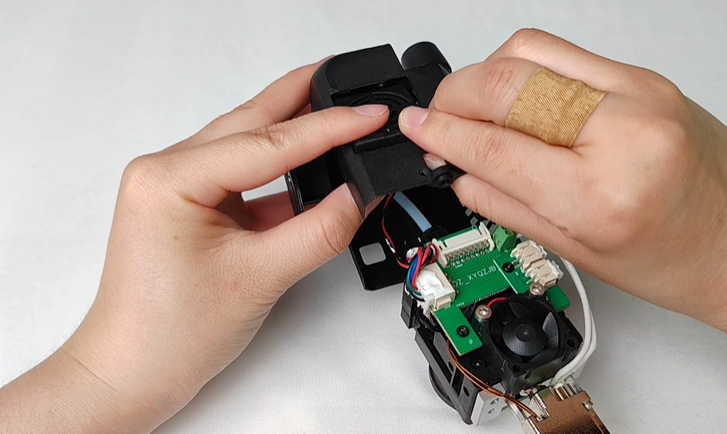

¶ (5). Take out the kit and remove the cooling fan fixed to the effector housing.

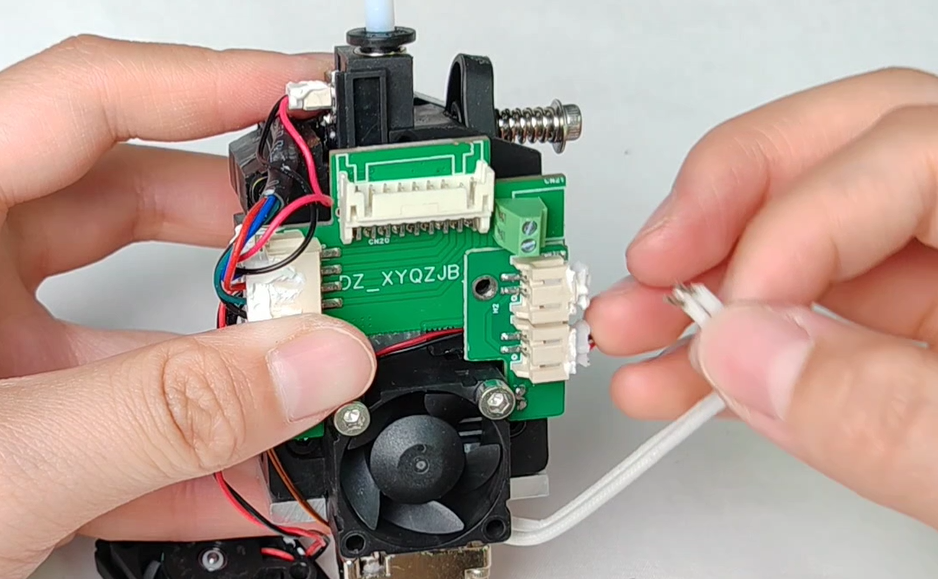

¶ (6). Unplug the heating rod circuit on the effector adapter plate, and use an H1.5 Allen wrench to remove the screws that fix the adapter plate.

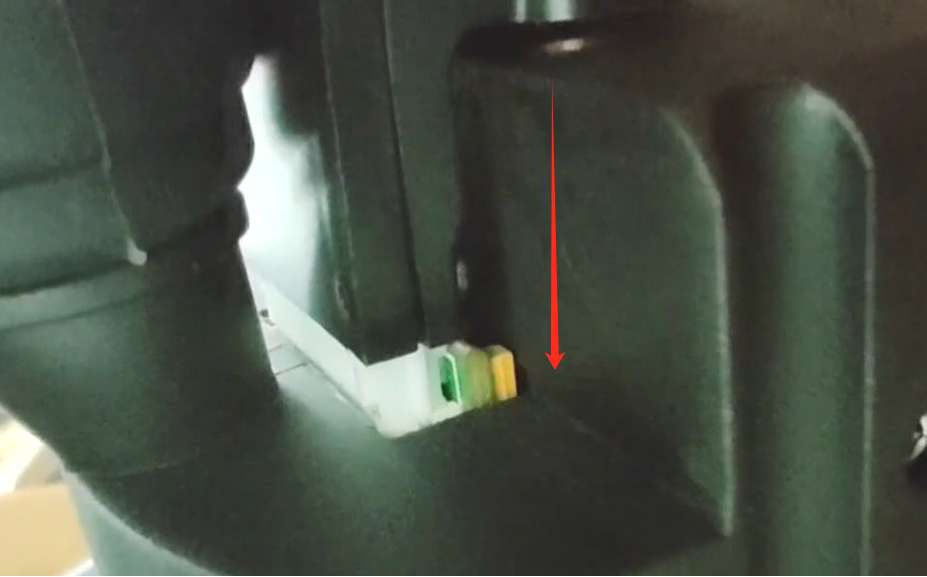

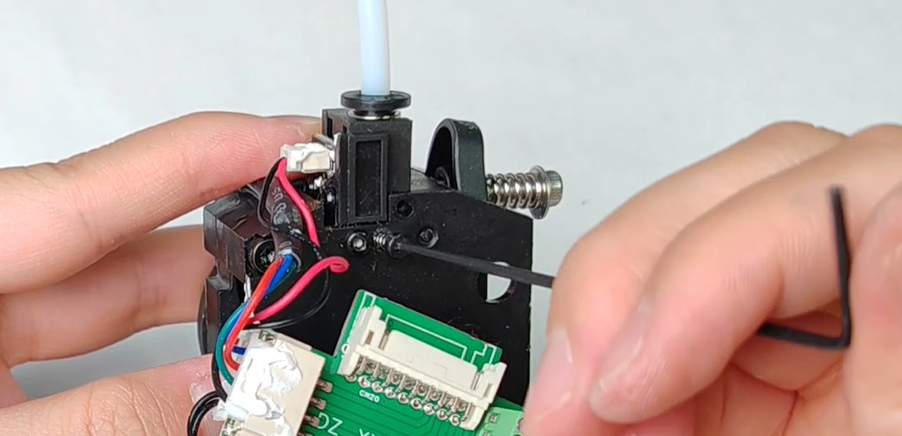

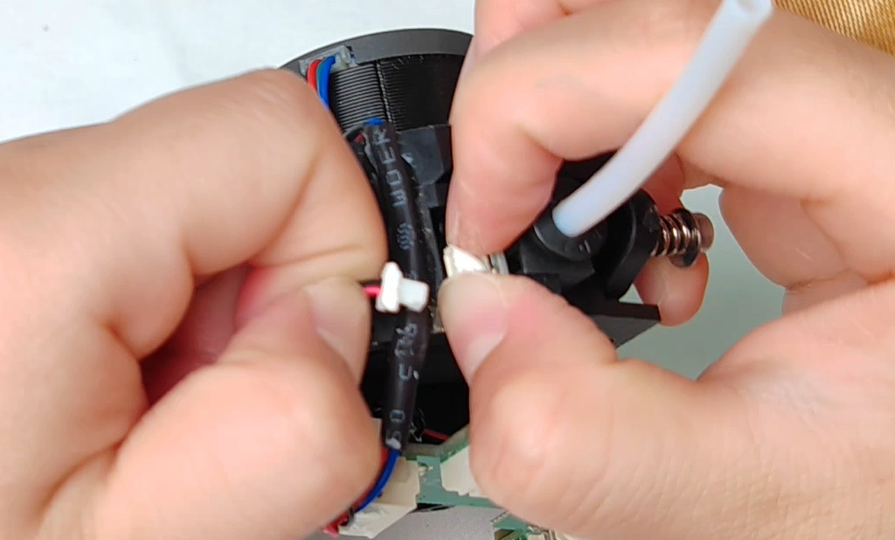

¶ (7). Use an H1.5 Allen wrench to remove the screws that fix the material break detection module and unplug the circuit.

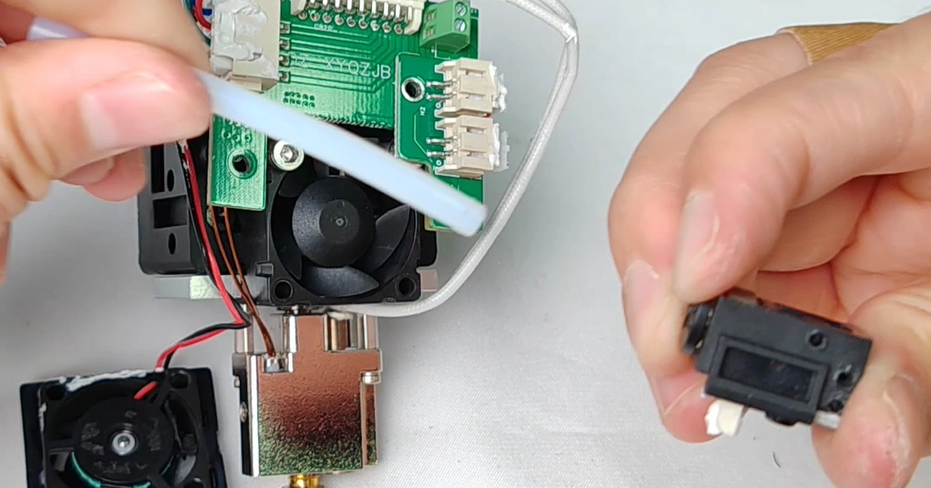

¶ (8). Take out the material break detection module and pull out the material tube.

¶ (9). Install a new material break detection module.

Note:

When installing the effector line, make sure that the effector line is inserted to the bottom.