¶ 1. Problem phenomenon

¶ (1). Click to feed, no filament is extruded;

¶ (2). The filament suddenly stops extruding during the printing process.

¶ 2. reason:

The nozzle or throat is clogged, and the extruder is blocked with filament.

¶ 3. solution:

Note: The disassembly operation needs to be carried out when the machine is powered off.

¶ (1). First, make sure that the filament is inserted all the way. If it is not inserted all the way, please unplug the pneumatic connector at the effector and insert the filament firmly here. Click feed, wait for the nozzle temperature to rise to 240°C, and automatically load the filament.

¶ (2). If the filament is extruded, use the silver needle in the accessory box to clear the nozzle, and click again to load the filament.

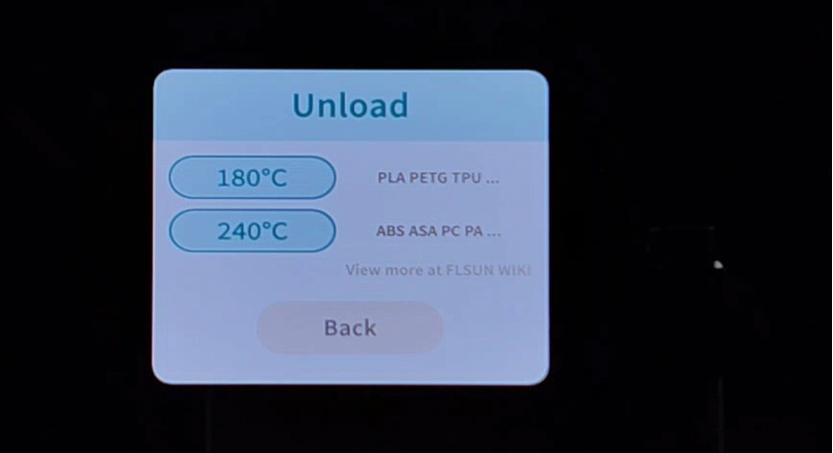

¶ (3). If there is still no filament extruded from the nozzle, try to exit the filament and click "Exit". A pop-up window will appear. Please select the appropriate temperature to exit the filament according to the printing filament. It is recommended that low-temperature filament be returned at 180°C, and high-temperature filament be returned at 240°C;

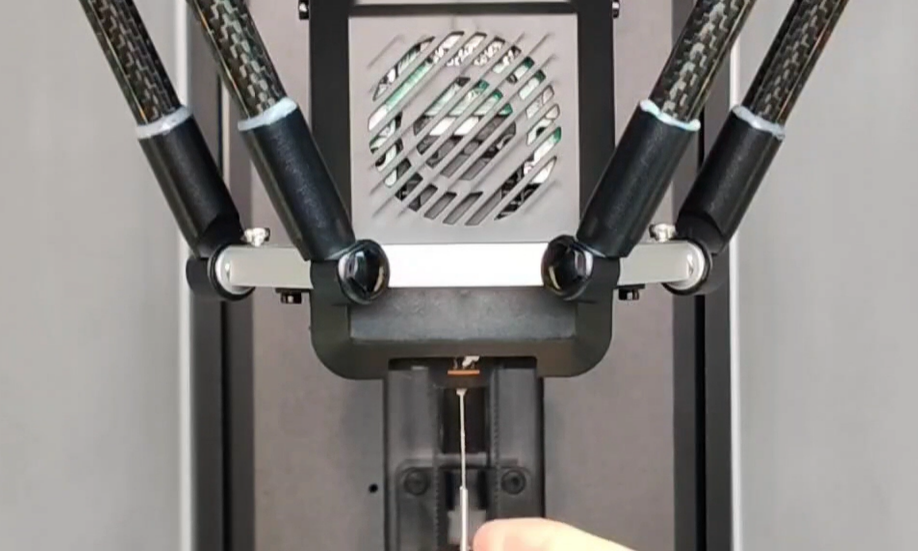

¶ (4). Unplug the pneumatic connector at the effector and pull out the filament;

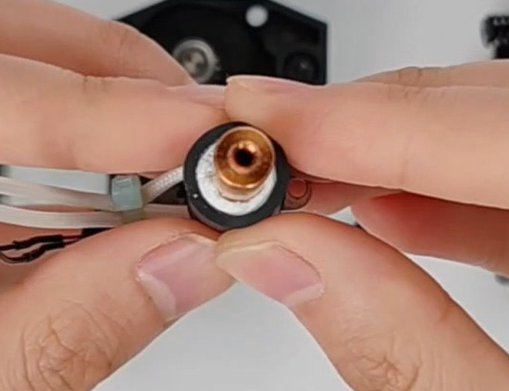

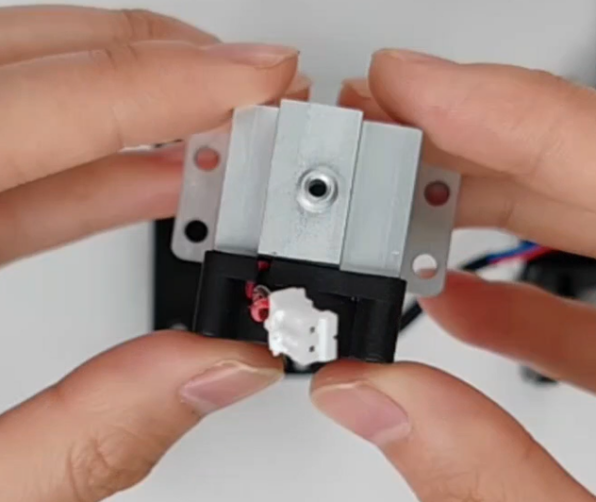

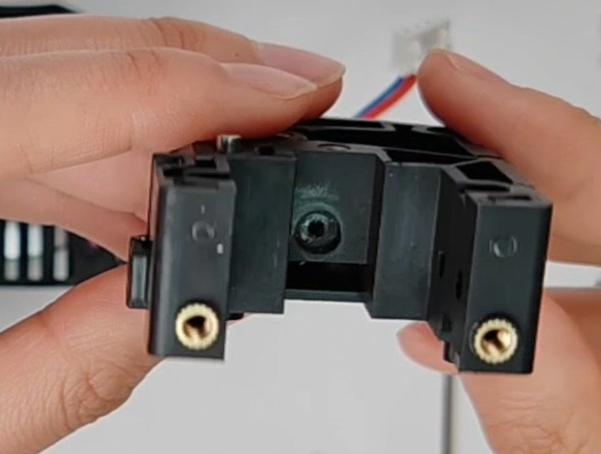

¶ (5). Disassemble the effector and check whether the throat or extruder is blocked;

¶ (6).The screws that secure the effector housing are on the back of the effector. This screw needs to be removed in order to remove the housing.