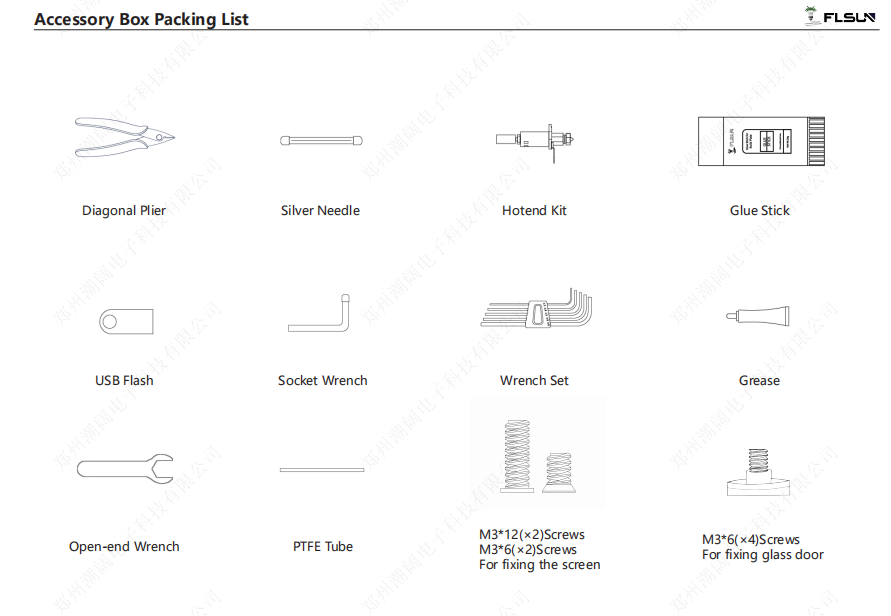

¶ 1. Diagonal Pliers:

Used to cut filaments, clean up support structures and excess materials after printing, and help refine the appearance of printed parts.

¶ 2. Silver Needle:

Used to unclog the nozzle (after heating the nozzle).

¶ 3. Hot End Kit:

Consists of a nozzle, heating block, throat pipe, heating ring, temperature sensor and heater. The hot end kit is mainly used to heat and extrude filaments in 3D printers. It heats the material to a molten state,extrudes the molten material through the nozzle, controls the temperature and prevents clogging through the cooling system.

¶ 4. Glue Stick:

As an auxiliary material in 3D printers, it is mainly used to improve adhesion, repair and fixation, temporary support and post-processing, providing additional convenience to the printing process.

¶ 5. USB Flash Drive:

The memory is 32GB, and the Gcode of the model can be imported in for printing.

¶ 6. Socket Wrench:

Used to remove the nozzle.

¶ 7. Hex Wrench:

It can be used to adjust or replace parts for printer maintenance and repair.

¶ 8. Grease:

Helps the printer maintain good performance by reducing friction and wear, improving motion accuracy and smoothness, and extending the service life of parts. You can squeeze grease on both sides of the T1 guide rail, slide the carriage up and down, repeat several times, so that the grease is evenly distributed on the guide rail, and apply grease to the ball heads at both ends of the parallel arm.

¶ 9. Open-end Wrench:

Used to fix the heater, so as to facilitate the disassembly and assembly of the nozzle.

¶ 10. PTFE Tube:

Transfer the filament to the hot end of the extruder for heating and extrusion to complete the printing process.

¶ 11. M312(x2), M32(x2) Screws:

For fixing the touchscreen.

¶ 12. M3*6(x4) Screws:

For fixing the glass door.