Reference video : https://youtu.be/2MVN-ePmVMw

1. Filament Sensor Module

When filament runout is detected, the printer will pause printing.

2. When to Replace the Filament Sensor Module

Replace the sensor if it is damaged.

3. Required Tools

- H1.5 hex wrench

- H2.0 hex wrench

- H2.5 hex wrench

- New filament sensor

4. Precautions

⚠️ If filament is loaded, heat the nozzle and unload the filament before disassembly.

⚠️ All disassembly must be done with the power off.

5. Replacement Steps

(1) Remove the cable clip and air duct

Use the H2.5 hex wrench from the accessory kit to remove the two screws securing the effector cable clip, then remove the cable and air duct.

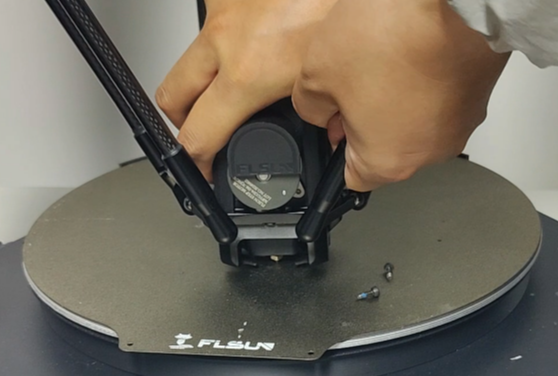

(2) Remove the effector

Detach the effector from the parallel arms.

(3) Remove the outer shell screws

Use the M2.5 hex wrench to remove the screws on both sides of the effector housing, and the H2.0 hex wrench to remove the screws on the back.

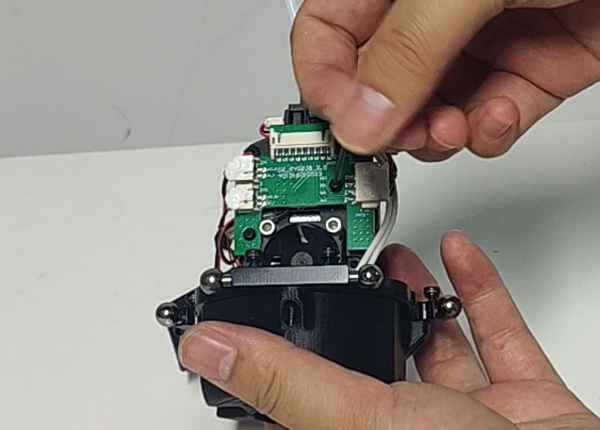

(4) Remove the housing and cooling fan

Carefully remove the effector housing and gently press the fan to take out the extruder cooling fan.

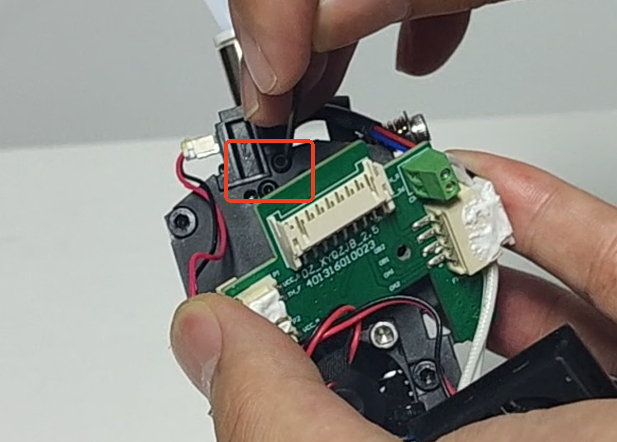

(5) Remove the adapter board screws

Use the H1.5 hex wrench to loosen and remove the screws securing the adapter board.

(6) Remove the filament sensor

Use the H1.5 hex wrench to remove the screws securing the filament sensor, disconnect the wires, and remove the old sensor.

(7) Install the new filament sensor

Install the new filament sensor and reassemble all parts as they were.