¶ Solution:

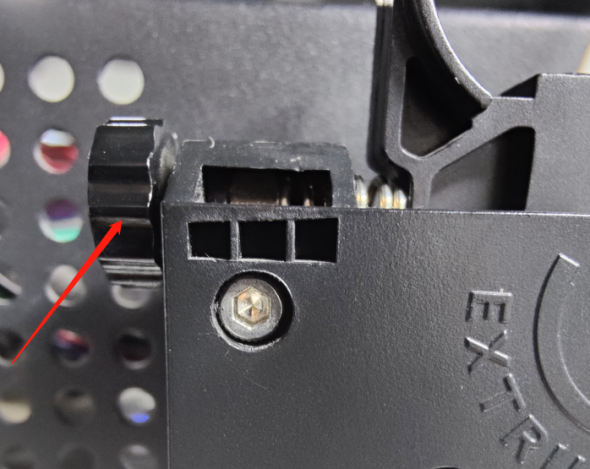

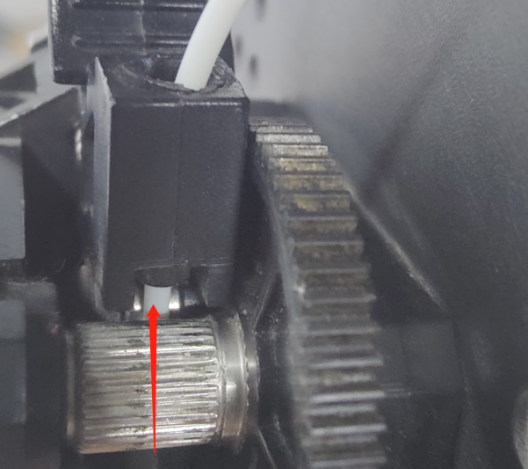

¶ 1. First check the extruder problem to ensure that the extruder screws are not loose and the filament is correctly loaded into the extruder.

¶ Manually feed the filament into the material tube about 3CM, then click "Tools>Change>Enter", wait for the nozzle to heat to 200℃, and see if the extruder can feed the filament into the nozzle. If so, the extruder No problem, if not, there may be a problem with the extruder and the extruder needs to be replaced.

¶ 2. Check whether the cooling fan on the hot end is working properly. If the cooling fan is not working, it is a blockage caused by insufficient heat dissipation and the fan needs to be replaced.

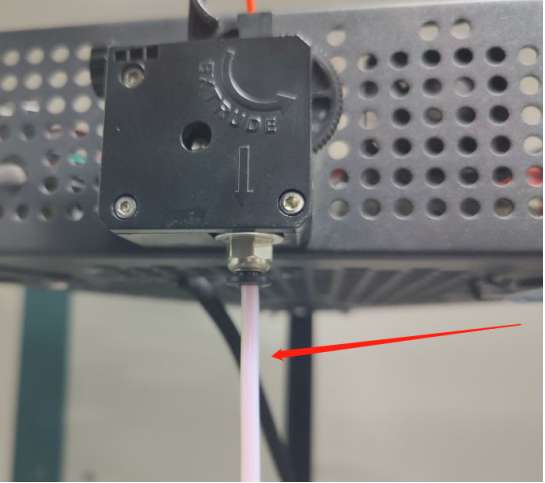

¶ 3. Clean the nozzle, heat the nozzle to 220°C, and use a silver needle to clear the nozzle. Try adding materials manually to see if any filaments are squeezed out of the nozzle.

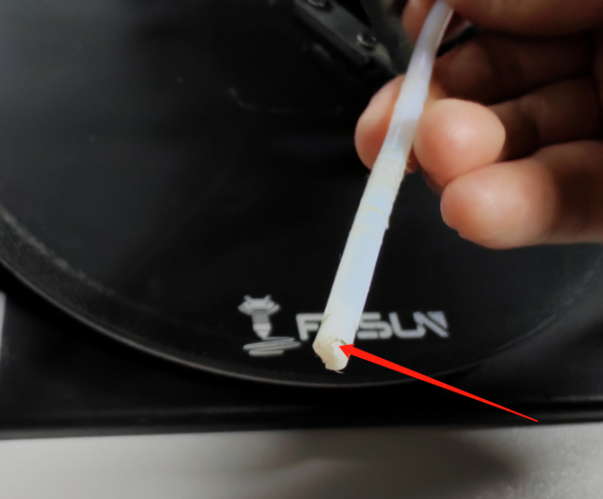

¶ 4. Check the material tube, pull out the material tube at the hot end, check whether the end of the polymer tube is blocked or melted, use scissors to cut off about 0.5-1CM, reinsert the material tube, and ensure that the material tube is plugged in At the end, try heating and extruding again.