The S1 machine has a molding size of up to 320x320x430mm. This is an assembled, fully enclosed 3D printer with a maximum printing speed of 1200mm/s and an acceleration of 40000mm/s². At the same time, it has excellent print quality through functions such as automatic leveling, vibration compensation, and flow calibration. The machine is equipped with AI lidar and a high-definition camera, which can issue a warning when printing fails. The heating bed also has a zoned intelligent heating function, which is more intelligent and environmentally friendly.

¶ 1.Nozzle

The S1 uses a short nozzle made of hardened steel, which is resistant to high temperatures, up to 350°, and wear-resistant. It is suitable for printing composite fliament such as carbon fiber.

¶ 2. Cooling device

Hot-end cooling: 2515 ordinary fans and heat sinks are used to dissipate heat from the hot-end throat to prevent premature melting of fliament caused by heat upload. 2515 ordinary fan is 5V, 15000 rpm.CPAP Turbo Fan: 37000 rpm, Minimum Cooling Time for Single Layer: 1 second. Function: Let the extruded material cool down quickly so that the model can be cooled and finalized in time, especially for models with overhanging structures.

¶ 3.Hot bed

It adopts silicone hot bed, 5mm aluminum plate, soft magnetic, PEI board, and uses Z-shaped fixings to fix the hot bed. It has better load-bearing, heat transfer and adhesion. The hot bed has two heating areas, which can be adjusted according to the model coordinate position. heating. Heating area: inner circle diameter 220mm, outer ring width 220-320mm.

¶ 4. Closed loop motor drive

The stepper motor of S1 adopts closed-loop control and has key technologies such as step number verification, step loss prevention, stall detection, and torque control. It has better stability, higher precision, high response, and high speed. In addition, it can Reduce motor heat.

¶ 5. Drying box

There are two ways to dry fliament, one is to use desiccant to dry the environment in the drying box, and the other is to heat and dry the drying box.

¶ 6. Binocular Structured Light System

It is a system structure composed of a set of cameras and a laser head. The principle is to use the laser head to project specific light information onto the surface and background of the object, then collect it by the camera. According to the changes in the light signal caused by the object, calculate the position and depth of the object and other information, and then restore the entire three-dimensional space.

AI LiDAR and binocular cameras are used for first-layer detection, flow calibration, and accuracy calibration.

1.First-layer detection:

Verify that there is no warping on the first layer, and the model cannot stick to the platform, to ensure the success rate of printing.

2.Flow calibration:

The gap between theoretical extrusion and actual extrusion, to determine whether the extrusion is normal.

3.Accuracy calibration:

To ensure printing accuracy.

¶ 7. Ordinary camera with X axis

Ordinary cameras can be used for real-time monitoring and time-lapse photography. When AI inspection is turned on, the camera can be combined to realize pasta detection and debris detection. When foreign objects or pasta are detected, printing will be paused and a warning will be issued.

¶ 8.Power supply

S1 uses a wide power supply, which can adapt to the voltage range of 110V-230V without manual adjustment settings

¶ 9. UPS Power Supply

S1 adopts a UPS power supply that delays power outages. When a sudden power failure occurs, the UPS power supply can provide a certain amount of power for the printer to maintain the short-term operation of the machine.

- Power-off resume print function: When a power failure occurs in the S1 machine, the UPS power supply will provide a certain amount of power. The printer can run for a short time to save data and reset the effector to prevent damage to the model. After the power is restored, it can continue to print the unfinished part without causing the entire printing task to fail.

- If an emergency occurs while the machine is running, be sure to first long press the On/Off button on the screen module for 1.5 seconds to stop the machine. Please do not turn off the power directly. If you turn off the power directly, the machine will start the UPS power supply by itself and will still run for a while.

¶ 10.Structural Light Calibration

¶ Role of structured light calibration:

Calibrate the internal and external parameters of the binocular camera to ensure the accuracy of the printer's structured light measurement.

¶ Usage scenarios:

- The camera is disassembled.

- There is a large error in the size of the printed model after accuracy calibration.

¶ Operation steps of structural light calibration:

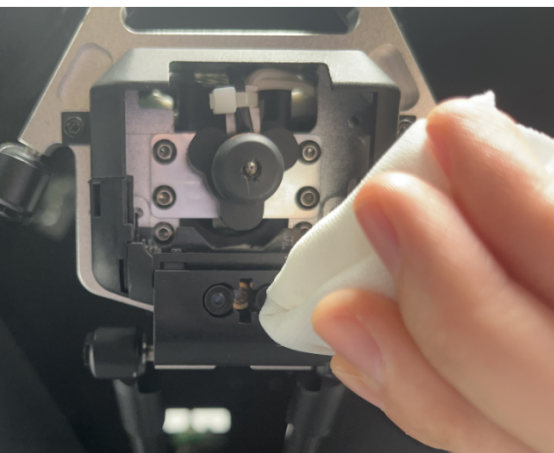

- Use alcohol cotton pads or wipes sprayed with alcohol to wipe the camera and calibration paper to keep them clean and tidy.

- Close the machine door.

- Connect to the network and log in to the web site.

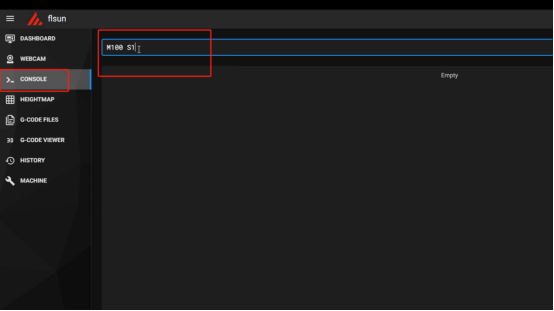

- Enter the command “M100 S1” into the console. After sending the command, the machine will perform the laser calibration, which takes about 4 minutes.

Reference video for structured light calibration:

https://youtu.be/xw-HWHhPKHI