¶ 1.Delta rapid motion system

FLSUN T1 adopts a delta motion system controlled by three stepper motors, with the X, Y, and Z motors working together to drive the parallel arm to move the print head to complete the printing. The high-current motors used in the T1 provide higher torque to ensure that no steps are lost in rapid printing. The Delta motion system allows T1 to print almost twice that of the traditional i3 structure and Core XY structure printers. Compared to the traditional i3 and Core XY printers that have 2 motors to control the print head movement, the T1 is powered by 3 motors to ensure fast movement by eliminating the need to move the bulky hotbed when printing.

¶ 2.Cooling system

FLSUN T1's CPAP turbo fan is designed for rapid model cooling during high-speed printing, with a maximum speed of 30,000 rpm/min. It guides the air to the bottom of the nozzle through the plastic ribbed tube and the air guide, which is also essential for high-speed printing, as it must cool the model in time for the next layer of printing.

¶ 3.High-flow hot end

The hot end is the part of the printer that melts the filament layer-by-layer deposited to create the model. Different types of filaments print at different temperatures. For example, PLA filament can be printed at a lower temperature, about 210-220℃, while other filaments (such as PETG and ABS) require higher temperatures, around 250-260℃.

The FLSUN T1 utilizes Flsun's self-developed high-temp hot end structure, which enables the filament to enter the hot end and melt quickly, ensuring high-flow extrusion during high-speed printing.

¶ 4.Extruder

The extruder is for pulling the filament from the spool, sending it to the hot end, melting it, and then pushing it through a small nozzle to generate a printed model. The FLSUN T1 adopts FLSUN's self-designed new HT dual-gear direct drive extruder, which precisely controls the amount of filament pushed through the hot end.

¶ Enclosure and Air Filtration

¶ Enclosure

Flsun T1 is equipped with an enclosure, the front door is glass and the side door is acrylic, which provides a highly closed printing environment to handle high-temperature filaments. Meanwhile, the side door is fixed with four fixings and can be removed at any time. In order to avoid clogging caused by the high temperature of the chamber, please open the front door if the local ambient temperature reaches 30℃ when printing PLA.

¶ Air filtration

Because printing ABS and other odorous consumables for a long period of time will produce harmful odors, the upper shell is equipped with an air filtration device that can be controlled from the screen to turn on the chamber fan, which can effectively exhaust the air inside the printer.

¶ 5.Camera and LED Light

¶ Camera

The camera on the Y-axis of the printer allows you to monitor your printing in real-time through the FLSUN Slicer, and the camera can record printing videos and save them locally for downloading and viewing via a USB flash drive.

In addition to mounting the camera inside the print chamber, you can also print the FLSUN-designed camera bracket to place the camera right in front of the printer chamber, so that you can get a more complete shot of the printed model.

¶ LED light

You can turn on the LED light on the Y-axis to make the print chamber brighter and better for shooting.

¶ Filament placement

The filament holder of Flsun T1 is inside the printing chamber and supports filaments of 1kg or less. To prevent tangling during printing, please pass the filaments through the clip.

Filaments of 1kg or less can be placed inside the chamber; filaments over 1kg can be placed outside the chamber and inserted into the chamber through the round hole on the top of the upper shell of the machine.

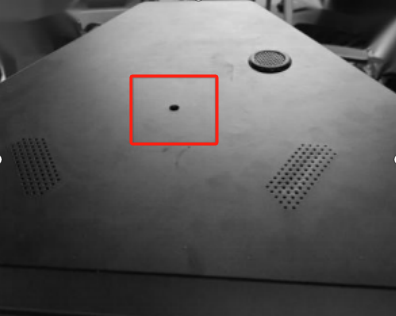

¶ 6.Fully automatic leveling

A pressure sensor is installed inside the hot bed, and the hot bed is leveled through the pressure sensor and automatic compensation. The pressure sensor works with the print head to achieve high-precision automatic leveling and ensure the success of the first layer of printing. There is no need to manually level the hot bed through A4 paper.

¶ 7.Vibration compensation

By detecting the resonance frequency of X/Y/Z axes and making intelligent adjustments to the motion control, it automatically compensates for machine resonance during high-speed printing, effectively eliminating vibration patterns on the models, and ensuring printing accuracy and stability.

¶ 8.Hot bed

The heat bed consists of thermal insulation cotton, aluminum substrate, soft magnet, and PEI plate. Its main function is to heat the printing surface and help the printed layers to better adhere to the printing platform. The heating temperature of the bed is set to different heating temperatures according to the different printing materials used, up to 110 ° C. The maximum printing area supported by the heated bed is ∅260m㎡.

The T1 PEI plate is magnetically attached to the heated bed and the limit blocks ensure that the PEI is correctly positioned and easily accessible; the PEI plate is textured on one side and smooth on the other, and can be used on both sides.

¶ 9.Belt tensioner

The printer is mainly driven by the motor rotating the belt, thereby driving the parallel arm and print head to realize precise movement. Long-term use will change the belt tension and thus affect the print quality. T1 three axes all have a belt tensioner. Loosen the two screws on the belt tensioner 3-4 turns to stretch the spring, and slide the parallel arm up and down, the belt will be automatically adjusted, and then tighten the screws for optimal performance.

¶ 10.Sensors and Electronics

Vibration compensation: Yes

Automatic leveling: Yes

Filament breakage detection: Yes

Power failure resume: Yes

Display: 4.3-inch color touchscreen

Storage: 8GB EMMC, 16GB USB Flash

Control interface: touch screen, PC application