¶ 1. Drying box

¶ (1) Reason: After absorbing a certain amount of water, it will gradually reach saturation and cannot absorb more water, thus losing its effectiveness.

¶ (2) Replacement period: Replace it every 3 months, depending on the ambient humidity.

¶ (3) How to replace: Take the old drying box out of the drying box and replace it with a new one.

Reference video:

https://youtu.be/CiWiba6UnOM

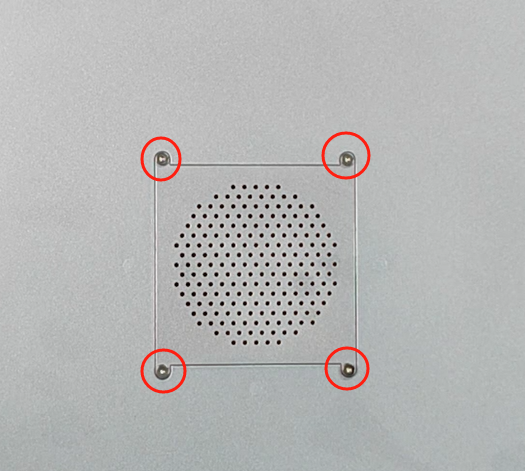

¶ 2. Air filter element

¶ (1) Reason: After absorbing a certain amount of substances, it will not be able to effectively absorb harmful substances, and the filtering effect will decrease.

¶ (2) Replacement period: If you frequently use consumables that produce harmful substances for printing, it is recommended to replace it every 1 month, depending on the consumables used.

¶ (3) How to replace: Use the H2.0 Allen wrench to remove the 4 screws that fix the air filter cover, remove the old air filter element, and replace it with a new one.

Reference video: https://youtu.be/KfkxW7St7HU

¶ 3. PEI board

¶ (1) Reason: A clean PEI board can increase the adhesion with the model, reduce the model falling off during printing, and improve the printing success rate; before each printing, you need to check whether there is dust or residual consumables on the PEI board. If there is, you need to clean it before printing.

¶ (2) How to clean: Use non-woven cloth dipped in water or alcohol to clean the PEI board

¶ (3) Note: Due to the fast printing speed, you can apply a solid glue stick before printing to increase adhesion or add skirts and brims to increase the adhesion surface to ensure the printing quality of the model.

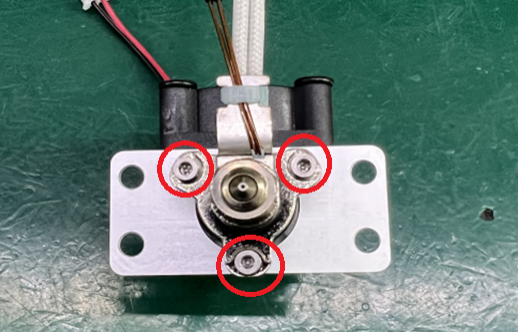

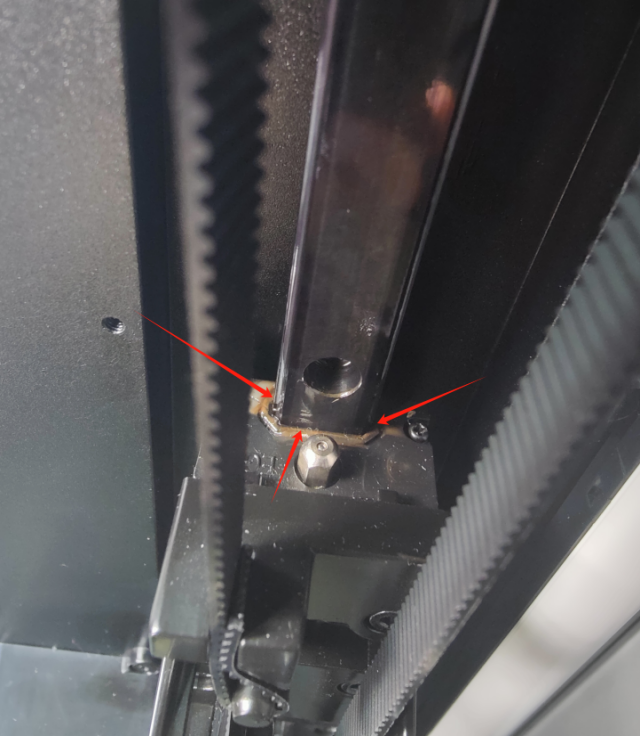

¶ 4. Nozzle Kit

¶ (1) Reason: The screws fixing the nozzle kit are loose, which will affect the printing quality and need to be checked regularly.

¶ (2) Maintenance period: Check once every 15 days or when print quality problems occur, depending on the printing situation of the printer.

¶ (3) How to maintain: Fix the nozzle kit screws: Remove the silicone sleeve and check whether the screws are loose. If so, tighten the screws in time.

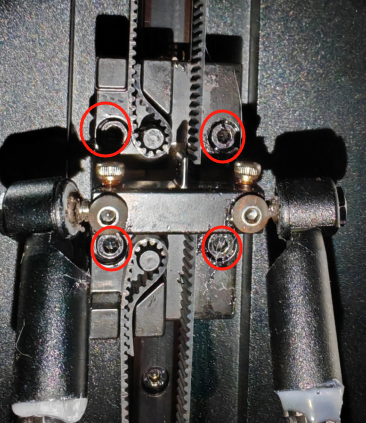

¶ 5. Linear guide rails and pulleys

¶ (1) Reason: The three linear rails need to be lubricated regularly. Proper lubrication can ensure smooth movement and extend service life. If the screws fixing the pulley are loose, it will affect the printing quality and should be checked regularly.

¶ (2) Maintenance period: Check once a month and add grease

¶ (3) How to maintain: Squeeze the grease on both sides of the linear guide rail, slide the pulley up and down, repeat several times, so that the grease is evenly distributed on the guide rail.

¶ Use an H3.0 wrench to check whether the screws of the pulleys of the three axes are loose. If so, tighten the screws.

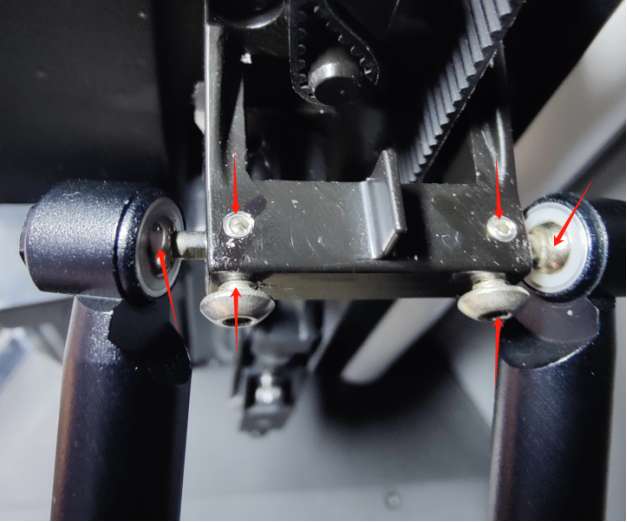

¶ 6. Parallel arm

¶ (1) Reason: The parallel arm is a motion joint that provides the movement of the actuator module. It is necessary to regularly check and tighten the screws and lubricate the ball head.

¶ (2) Maintenance period: Check once a month.

¶ (3) How to maintain: Check whether the screws at each connection of the parallel arm are loose, and tighten the screws with a wrench; apply grease to the ball heads at both ends of the parallel arm.

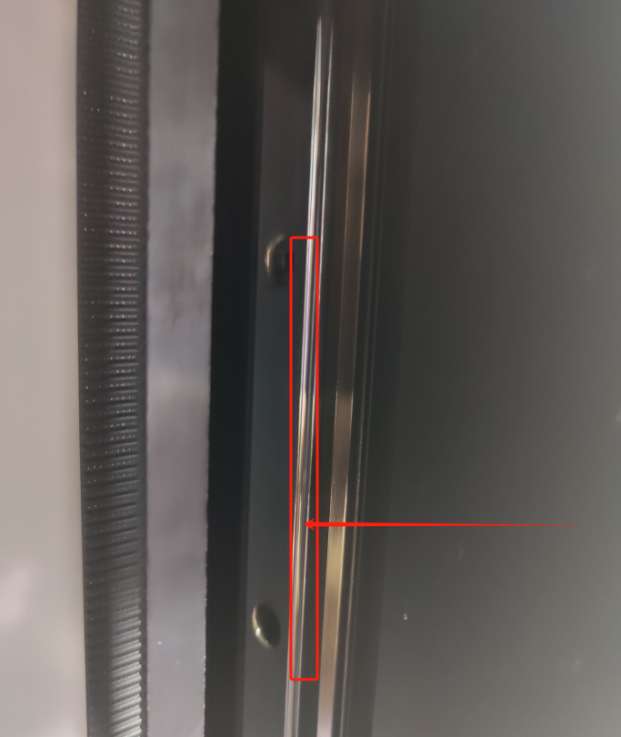

¶ 7. Belt

¶ (1) Reason: The belt slider provides precise movement of the machine

¶ (2) Maintenance period: The belt should be checked once a month, and whether the tension should be adjusted depends on the usage.

¶ (3) How to maintain: Loosen the two screws on the belt adjuster 3-4 turns to stretch its spring, slide the parallel arm up and down, the belt will automatically tighten, and then tighten the screws.

Belt adjustment video:

https://youtu.be/2aKw2y00DqY

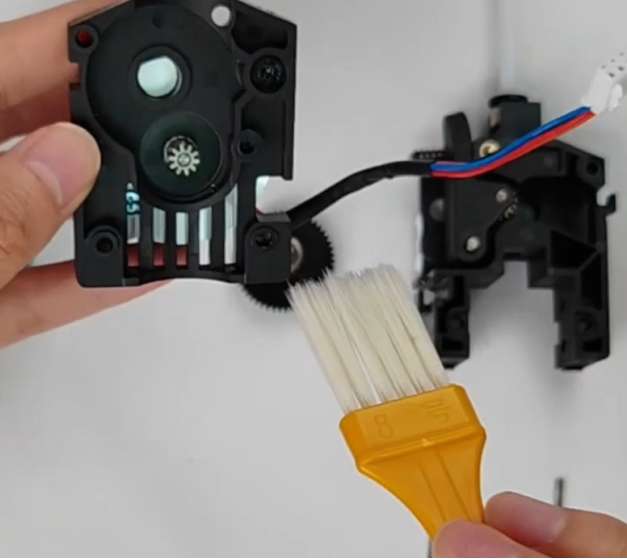

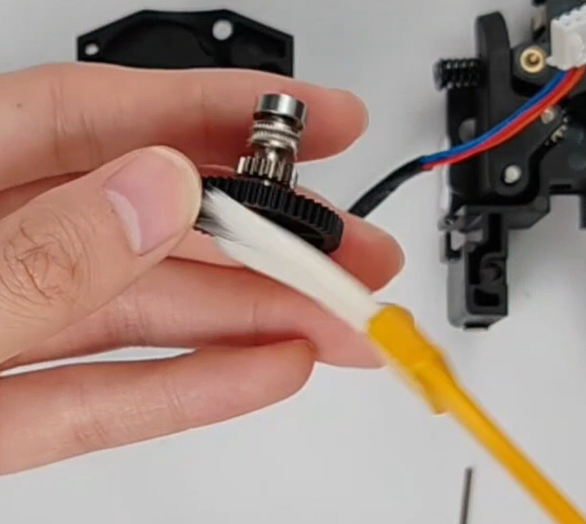

¶ 8. Extruder

¶ (1) Reason: Removing debris from the wire feed wheel can reduce the risk of material loss and blockage, ensuring smooth operation and long service life

¶ (2) Maintenance period: It is recommended to check once a month and remove the debris of the wearing parts on the wire feed wheel, depending on the actual use.

¶ (3) How to maintain: Operate the extruder to rotate and use a soft brush to remove the debris on the wire feed wheel.

Note: Refer to the video of the material blockage to check the operation.

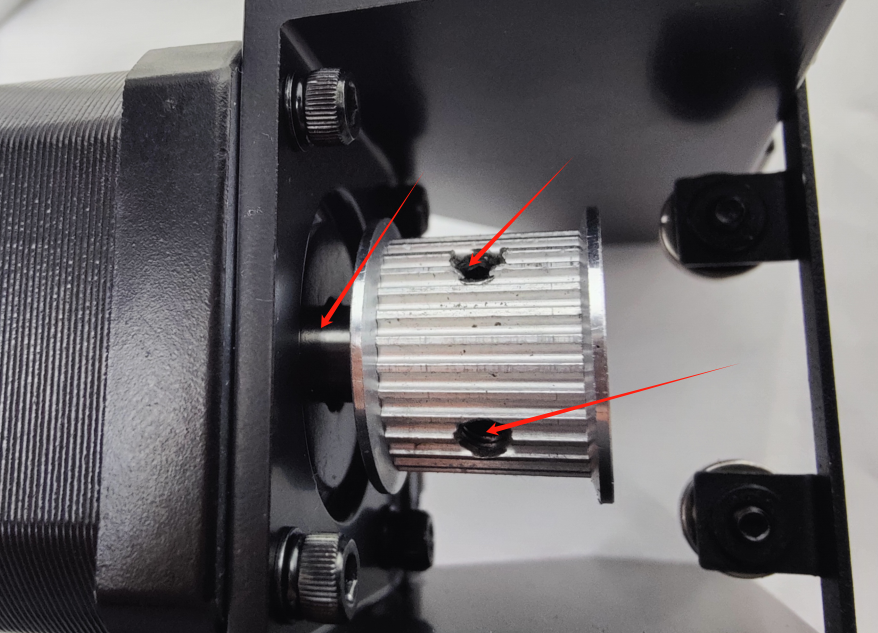

¶ 9. Shaft motor synchronous wheel and bearings

¶ (1) Reason: Proper lubrication and reinforcement will ensure smooth operation and long service life.

¶ (2) Maintenance period: It is recommended to check once every two months, depending on the usage.

¶ (3) How to maintain: Remove the motor, check whether the synchronous wheel gear is loose, tighten the screws; turn the synchronous wheel and drip liquid lubricant onto the bearing.

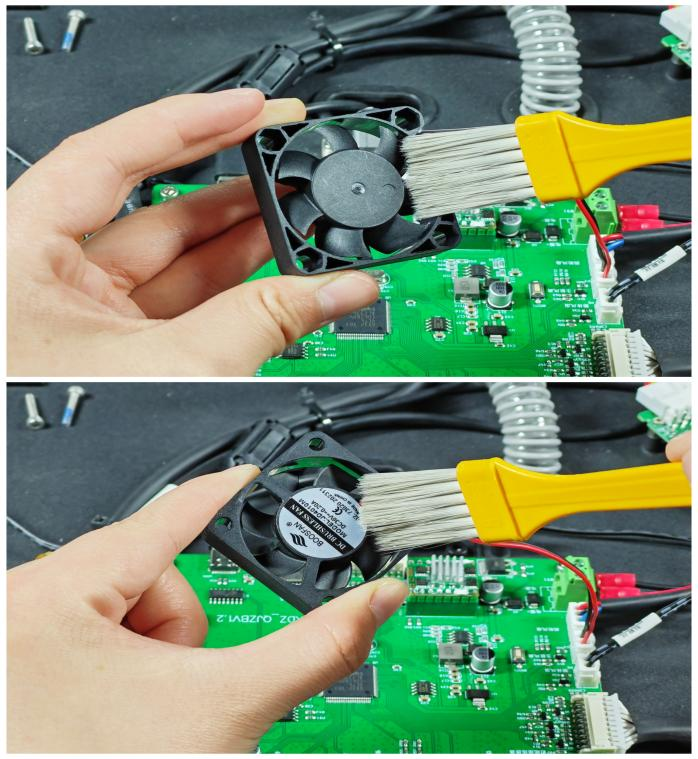

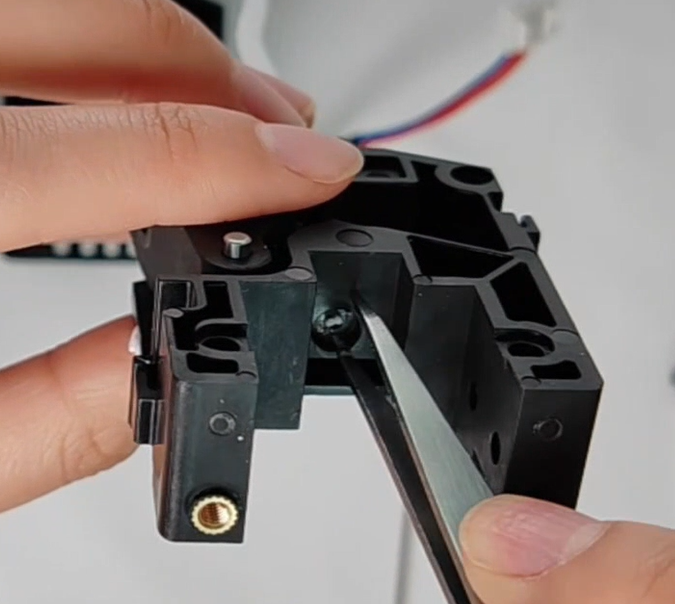

¶ 10. Motherboard and motherboard fan

¶ (1) Reason: When the motherboard is dusty, it may affect the use of the printer. When the motherboard fan is dusty, it will affect the heat dissipation effect.

¶ (2) Maintenance period: The motherboard and fan should be checked and cleaned after about half a year of use; if your printing environment is dusty, the cleaning frequency can be increased appropriately.

¶ (3) Maintenance: After turning off the power of the machine, open the top cover and use a brush to clean the motherboard area.

¶ To clean the fan, remove the screws, hold the fan, and clean both sides.